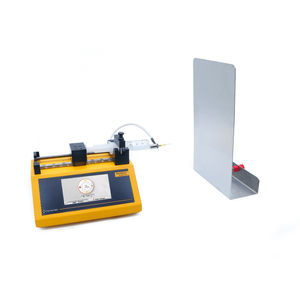

Nanofiber electrospinning machine NE300laboratorycompactmulti-nozzle

Add to favorites

Compare this product

Characteristics

- Applications

- nanofiber, laboratory

- Other characteristics

- compact, multi-nozzle, spraying

Description

The NE300 Electrospinning Machine, is a compact, flexible lab-scale Electrospinning system. Very similar to the NS 24 but with less emitters (8 nozzles), also has the capacity of single-nozzle production. This model has a homogeneity system that enables uniform coating of the nanofibers membrane. The NE 300 has an Electrically insulated cabinet with high density PE parts inert to chemical solutions, which enables working with many polymers. Many optional features can be added to the system, such as Co-axial System for core-shell, hollow and bi-component nanofibers.

Unique Properties

Reliable and precise process adjustments via 9” touch screen panel

Bottom-Up spinning

Up to 8 Nozzles for High-throughput electrospinning

314mm*220mm coating area

Electrically insulated cabinet with high density PE parts inert to chemical solutions

Automatic control of voltage, flow rate and collector motion (z-axis, x-axis and rotation)

Extra safety options such as safe-door and warning light to avoid from high voltage

Different Diameter Needles

Electrospinning needles with the following diameters: (23G, 21G, 19G, 17G, 15G) X10 pieces.

Bicomponent System

Two special designed coaxial nozzles:

Shell Nozzle

(ID : 0.337 mm, OD: 3.3 mm)

Core nozzle

(ID: 0.6414 mm, OD: 1 mm)

and an extra syringe pump to obtain core-shell, hollow and bicomponent nanofibers.

Gas Shield Nozzle

Gas Shield is a way to solve clogging of polymer on the top of needle by solvent saturated N2 gas. This option may increase productivity of many polymer solutions.

Rotating Shaft Collector

3-4-5 and 6 mm diameter rotating shaft collectors for tubular nanofiber membrane production.

Catalogs

NE300

4 Pages

Electrospinning Machines Catalog

32 Pages

Related Searches

- Electrospinning machine

- Nanofiber electrospinning machine

- Laboratory electrospinning machine

- Industrial electrospinning machine

- Programmable electrospinning machine

- Compact electrospinning machine

- Non-woven electrospinning machine

- Electrospinning machine with touch screen

- Pilot plant electrospinning machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.