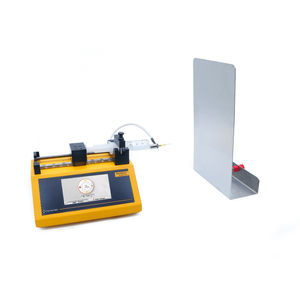

Nanofiber electrospinning machine NE100programmablesingle-nozzlespraying

Add to favorites

Compare this product

Characteristics

- Applications

- nanofiber

- Other characteristics

- programmable, single-nozzle, spraying

Description

The NE100 Electrospinning Unit, a model that is in between basic and advanced Electrospinning systems, all process parameters can be edited from its programmable easy-to-use touch screen panel. It also has a special designed isolated chassis and an exhaust system that enables working with evaporative solvents. Because of the door safety system and the isolated chassis, scientists can carry out their experiments safely.

Brief Explanation

The Ne100 is a easy to use, single-nozzle electrospinning unit, designed for small scale production of nanofiber. The protected cabined avoids any danger which may be caused by high voltage or solvent vapor. The model is included in Inovenso Scale Up Program, allows for users upgrading their devices to more advanced models.

Unique Properties

Reliable and precise process adjustments via 9” touch screen panel

High throughput production with special single nozzle

Flat collector for nanofiber deposition

Different Diameter Needles

Electrospinning needles with the following diameters: (23G, 21G, 19G, 17G, 15G) X10 pieces.

Bicomponent System

Two special designed coaxial nozzles:

Shell Nozzle

(ID : 0.337 mm, OD: 3.3 mm)

Core nozzle

(ID: 0.6414 mm, OD: 1 mm)

and an extra syringe pump to obtain core-shell, hollow and bicomponent nanofibers.

Gas Shield Nozzle

Gas Shield is a way to solve clogging of polymer on the top of needle by solvent saturated N2 gas. This option may increase productivity of many polymer solutions.

Rotating Shaft Collector

3-4-5 and 6 mm diameter rotating shaft collectors for tubular nanofiber membrane production.

Temperature Controlled Chamber

Heating of spinning area up to 40°C.

Catalogs

Electrospinning Machines Catalog

32 Pages

Related Searches

- Electrospinning machine

- Nanofiber electrospinning machine

- Laboratory electrospinning machine

- Industrial electrospinning machine

- Programmable electrospinning machine

- Compact electrospinning machine

- Non-woven electrospinning machine

- Electrospinning machine with touch screen

- Pilot plant electrospinning machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.