- Industrial machines and equipment

- Furnace and Heat Treatments

- Chamber oven

- INSERTEC INDUSTRIAL FURNACES INSERTEC, S.L.U.

Chamber furnace meltingholding

Add to favorites

Compare this product

Characteristics

- Configuration

- chamber

- Function

- melting, holding

Description

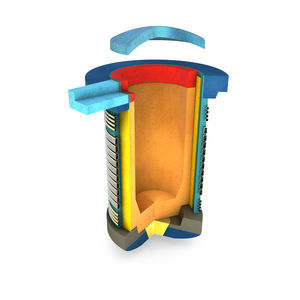

In aluminium foundry plants, melting towers often have problems with corundum regrowth. It is a serious problem that can lead to wear, loss of energy efficiency and destruction of the lining.

To minimise this, Insertec has developed a wide range of refractory solutions including castables and precast shapes (nose Beam, impact area...).

Precast shapes \

Regrowth of corundum = destruction of the lining.

Wear and loss of energy efficiency. Melting Tower with precast shapes (load nose and impact blocks) managed to improve these losses.

Images description (in order)

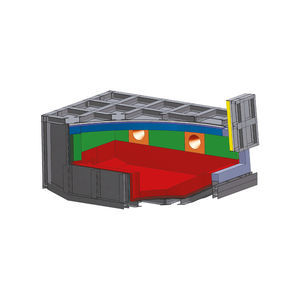

Nose Beam - Precast Piece

Channel between melting and holding chambers

Impact area with precast pieces after 3 years working

Frame

Catalogs

No catalogs are available for this product.

See all of INSERTEC INDUSTRIAL FURNACES INSERTEC, S.L.U.‘s catalogsOther INSERTEC INDUSTRIAL FURNACES INSERTEC, S.L.U. products

Aluminium foundry

Related Searches

- Furnace

- Chamber furnace

- Electric furnace

- Heat treatment furnace

- Drying furnace

- Automatic furnace

- Continuous furnace

- Melting furnace

- Thermal furnace

- Sintering furnace

- Rotary furnace

- Induction furnace

- Preheating furnace

- Steel furnace

- Graphite furnace

- Cleaning furnace

- Casting furnace

- Holding furnace

- Pouring furnace

- Thermal shock furnace

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.