- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

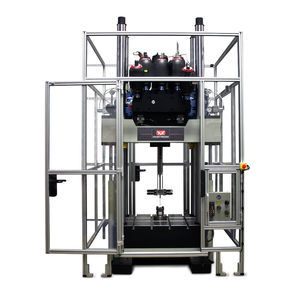

Fatigue testing machine ElectroPuls E1000PC-controllablematerialfor research and development

Add to favorites

Compare this product

Characteristics

- Test type

- fatigue

- Operating mode

- PC-controllable

- Test material

- material

- Sector

- for research and development, for the electronics industry, for medical applications

- Technology

- dynamic, electric

- Configuration

- vertical

- Other characteristics

- static, double-column

Description

The ElectroPuls® E1000 is a state-of-the-art, all-electric test instrument designed for dynamic and static testing on a wide range of materials and components. It includes Instron® advanced digital control electronics, Dynacell™ load cell, Console software, and the very latest in testing technology – hasslefree tuning based on specimen stiffness, electrically operated crosshead lifts, a T-slot table for flexible test set ups and a host of other user-orientated features.

Powered from a single-phase supply it requires no additional utilities for basic machine operation (for example, pneumatic air, hydraulics, or water).

FEATURES

• Patented, oil-free linear motor technology for clean conditions

• Designed for both dynamic and static testing on a variety of materials and components

• High dynamic performance, capable of operating at over 100 Hz

• ±1000 N dynamic load capacity and ±710 N static load capacity

• Electrically powered from single phase main supply, no need for hydraulic or pneumatic air supplies

• Temperature-controlled air-cooling system

• High-stiffness, precisionaligned twin column load frame with actuator in upper crosshead

• Versatile T-slot table for regular and irregular grips and specimens

• Compact instrument - frame requires less than 0.15 m² (1.6 ft²) of desk space

HARDWARE AND SOFTWARE INTERFACES DESIGNED TO PUT YOU IN CONTROL

• Console software control interface - engineered with Instron’s knowledge of machine usability

• Rigidly mounted control pod with critical controls and emergency stop at your fingertips

• Electrically powered crosshead lift system with manual lever clamps for ease of test space adjustment

Catalogs

Related Searches

- Instron testing machine

- Test cabinet

- Test stand

- Instron material testing machine

- Instron automatic testing machine

- Instron computer-controlled testing machine

- Instron compression testing machine

- Instron vertical testing machine

- Instron industrial testing machine

- Instron universal testing machine

- Instron tensile testing machine

- Instron bending testing machine

- Instron laboratory testing machine

- Instron precision testing machine

- Instron research and development testing machine

- Instron electromechanical testing machine

- Environmental test cabinet

- Instron hydraulic testing machine

- Instron plastic testing machine

- Instron tension testing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.