- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

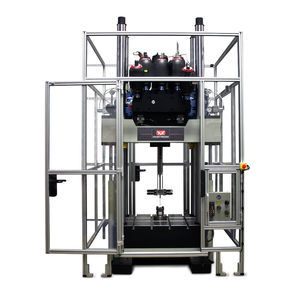

Fatigue testing machine 8803PC-controllablematerialfor laboratories

Add to favorites

Compare this product

Characteristics

- Test type

- fatigue

- Operating mode

- PC-controllable

- Test material

- material

- Sector

- for laboratories

- Technology

- servo-hydraulic, dynamic

- Configuration

- vertical

- Other characteristics

- static, double-column

Description

The Instron® 8803 is a versatile servohydraulic fatigue testing system that performs static and dynamic tests on materials and components up to 500 kN. 8803 systems provide complete testing solutions to satisfy the needs of advanced materials and component testing, and are ideally suited for fatigue testing and fracture mechanics. This features a large number of configurations and options, including lower t-slot tables, the 8803 makes an ideal platform for any laboratory.

FEATURES

• Double-acting servohydraulic actuator with force capacity up to ±500 kN (±110 kip)

• High-stiffness, precision-aligned load frame with twin columns and actuator in lower base or upper crosshead

• Designed for both dynamic and static testing on a variety of materials and components

• Choice of hydraulic configuration and dynamic performance to suit application

• Extra-height and Extra-extra height frame options for testing longer load strings

• Adjustable upper crosshead with hydraulic lifts and lock fitted as standard for easy adjustment of daylight

• Up to 250 mm (9.8 in) of usable stroke

• Patented1 Dynacell™ advanced load cell technology for faster testing and reduction of inertial errors

• Floor-standing servohydraulic fatigue testing system–frame requires less than 1.6 m² (16.6 ft²) of floor space

• Hydrostatic bearing actuators for high side-load resistance and better alignment during testing

• Designed to be used with the 3520 Series of Hydraulic Power Units

• Compatible with a large range of grips, fixtures, chambers, video extensometers, protective shields, and other accessories

Related Searches

- Instron testing machine

- Test cabinet

- Test stand

- Instron material testing machine

- Instron automatic testing machine

- Instron computer-controlled testing machine

- Instron compression testing machine

- Instron vertical testing machine

- Instron industrial testing machine

- Instron universal testing machine

- Instron tensile testing machine

- Instron bending testing machine

- Instron laboratory testing machine

- Instron precision testing machine

- Instron research and development testing machine

- Instron electromechanical testing machine

- Environmental test cabinet

- Instron hydraulic testing machine

- Instron plastic testing machine

- Instron tension testing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.