- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Curved needle test machine forceflexurecomputer-controlled

Add to favorites

Compare this product

Characteristics

- Test type

- force, flexure

- Operating mode

- computer-controlled

- Test material

- for multiple samples, for metallic materials, for curved needle

- Sector

- for laboratories, for research and development, for quality control, for the pharmaceutical industry

- Technology

- mechanical

- Other characteristics

- single-column

Description

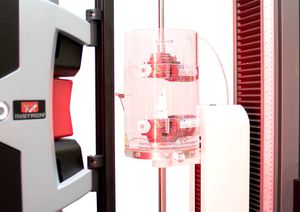

The Instron® Curved Needle Testing System is ideally suited for testing needles used in wound closure or surgical procedures. This system provides a platform for two different needle testing solutions: one for curved needle puncture testing to ASTM F3014 and the other for cantilever bend testing. The curved needle puncture testing fixture is used to evaluate needle sharpness and coating durability, while the needle bend testing fixture is used to evaluate flexural properties of the needle during use. With its tabletop design, the Curved Needle Testing System has a small footprint and takes up minimal bench-top space. The testing system operates with Bluehill® Universal software that provides test control, data acquisition, test results, and reports, as well as a large library of calculations.

Specifications:

• Maximum Angular Displacement: 140°

• Angular Displacement Resolution: 0.015°

• Minimum Angular Velocity: 0.06 °/sec

• Maximum Angular Velocity: 100 °/sec

• Needle Size: R2.44 – R32.3 (radius)

• Needle Gauge: 0.44 – 1.13 mm

• Electrical Requirements: Single Phase, 47/63 Hz, 120 or 220 VAC

• Operating Temperature: +10 to 38°C or +50 to 150°F

• Software: Bluehill Universal

VIDEO

Catalogs

No catalogs are available for this product.

See all of Instron‘s catalogsRelated Searches

- Instron testing machine

- Test cabinet

- Test stand

- Instron material testing machine

- Instron automatic testing machine

- Instron computer-controlled testing machine

- Instron compression testing machine

- Instron vertical testing machine

- Instron industrial testing machine

- Instron universal testing machine

- Instron bending testing machine

- Instron tensile testing machine

- Instron laboratory testing machine

- Instron precision testing machine

- Instron electromechanical testing machine

- Instron research and development testing machine

- Instron hydraulic testing machine

- Environmental test cabinet

- Instron tension testing machine

- Instron plastic testing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.