- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Injection testing machine automatedfor plasticsfor laboratories

Add to favorites

Compare this product

Characteristics

- Test type

- injection

- Operating mode

- automated

- Test material

- for plastics

- Sector

- for laboratories, for research and development, for the pharmaceutical industry

- Technology

- camera

- Configuration

- tabletop

- Other characteristics

- static

Description

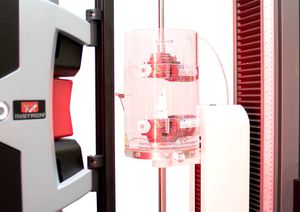

Instron’s Autoinjector Testing System is capable of performing full functionality testing on drug delivery devices, including needle shield and button activated devices, in addition to safety syringes. Developed in close partnership with pharmaceutical device manufacturers and CDMOs, the system measures a variety of performance requirements, including cap removal, dose accuracy, activation force, injection time, needle depth, click detection, and needle guard lockout, allowing organizations to meet internal quality requirements and international testing standards such as ISO 11608.

The Autoinjector Testing System replaces traditional test procedures that typically involve separate pieces of equipment, empowering users to run a complete sequence of tests on a single system and allowing manufacturers to accelerate time to market through:

• Reduction in overall testing time and number of devices required

• Cost reduction in terms of testing equipment, maintenance, and specimens

• Simplified data consolidation, analysis, and validation process

• Streamlined tech transfer to production sites

Features

• Dedicated test methods in Bluehill Universal software that are simple to create and easy to modify

• Integrated system suitability testing that prompts users to preform admin defined daily checks of the load cell, machine vision camera, and scale per internal requirements and Good Manufacturing Practices

• Machine Vision Camera that provides high-accuracy optical measurements of injection time and exposed needle depth at the start and end of injection

• High resolution video camera and machine vision camera provide critical visuals for root cause analysis

VIDEO

Catalogs

Related Searches

- Instron testing machine

- Test cabinet

- Test stand

- Instron material testing machine

- Instron automatic testing machine

- Instron computer-controlled testing machine

- Instron compression testing machine

- Instron vertical testing machine

- Instron industrial testing machine

- Instron universal testing machine

- Instron tensile testing machine

- Instron bending testing machine

- Instron laboratory testing machine

- Instron precision testing machine

- Instron research and development testing machine

- Instron electromechanical testing machine

- Environmental test cabinet

- Instron hydraulic testing machine

- Instron plastic testing machine

- Instron tension testing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.