- Metrology - Laboratory

- Optical Component

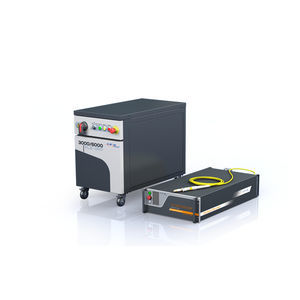

- Continuous laser

- IPG Photonics Corporation

Continuous laser DLS-ECO Seriesolid-stateinfraredhigh-power

Add to favorites

Compare this product

Characteristics

- Operational mode

- continuous

- Technology

- solid-state

- Spectrum

- infrared

- Applications

- industrial, high-power

- Other characteristics

- high-power, diode

- Power

100,000 W

- Wavelength

958 nm, 960 nm

Description

The DLS-ECO Laser Heater replaces less efficient infrared bulbs and slower, environmentally unfriendly gas fired furnaces. Extremely high power conversion efficiency along with exceptionally low impact on the ambient factory environment make the cost of ownership and return on investment of a laser heater compelling. DLS-ECO is an excellent solution to dry industrial coatings such as paint or battery slurries, cure powder coat or heat silicon wafers.

The DLS-ECO Series announces the arrival of solid-state heating to replace less efficient infrared bulbs and environmentally unfriendly gas fired furnaces. High 55% electric conversion efficiency along with exceptionally low impact on the ambient factory environment make the Cost-of-Ownership and Return-on-Investment of a diode heater compelling.

A diode heater operates cold, wasting no energy warming insulating walls or the factory floor. Rather, all energy is highly directed as laser light onto the media being processed. Between batches the diode heater is off, not idling, so no energy is consumed when it is not needed.

Laser light dries below the surface providing a more efficient process than is possible in a thermal convection oven, meaning a DLS-ECO solution is up to 4X smaller and up to 4X faster. The open, cool environment is inviting to thermal metrology enabling tighter process control benefitting from instantaneous, on-the-fly temperature adjustments. The DLS-ECO is well suited to dry coatings such as lithium-ion battery electrode slurries, or to cure paint or powder coat.

VIDEO

Catalogs

No catalogs are available for this product.

See all of IPG Photonics Corporation‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.