- Products

- Catalogs

- News & Trends

- Exhibitions

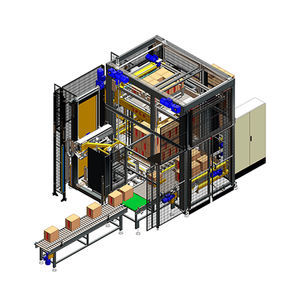

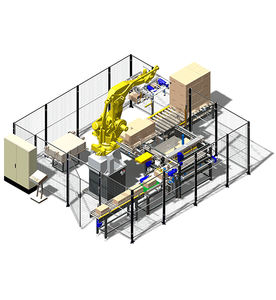

Robotic palletizer ALL-ROUND PALhandlingboxpallet

Add to favorites

Compare this product

Characteristics

- Type

- robotic

- Product applications

- handling, box, pallet

- Throughput

Min.: 0 p/min

Max.: 60 p/min

- Pallet width

800 mm, 1,000 mm

(31.5 in, 39.37 in)- Pallet length

1,200 mm

(47.24 in)- Pallet weight

220 kg

(485.02 lb)- Maximum palletizing height

800 mm, 2,400 mm

(31.5 in, 94.49 in)- Overall weight

315 kg

(694 lb)

Description

The ALL-ROUND PAL palletising cell is characterised by arms that rotate and position each box on the route to the forming table.

This makes it capable of configuring any kind of pattern with stacking boxes.

Furthermore, its comb and plate gripper lifts boxes from underneath and holds them on the sides, ensuring palletising of the box in perfect condition, even with previous sealing errors, while allowing variability in box size as the gripper palletises complete layers.

Main advantages

TABLE

- Rotational and positional handling.

- Any kind of pattern with stacking boxes.

GRIPPER

- Secure and versatile.

IPLA ROBOT SOFTWARE

The control software developed by IPLA provides total control of the pallet cell without needing to use the robot console, making use easier and removing the need for a programmer to make modifications.

The touch-screen control interface allows manual control of all cell elements, displaying alert zones with active photocell indicators.

There is also the possibility of configuring new palletising formats, generating patterns by indicating the movements that each box much make.

Furthermore, it offers production information like the number of palletised boxes and pallets, rate of production and more.

Optional extras

This cell offers the possibility of the robot placing cardboard interlayers between pallet layers by installing a cardboard store within the cell.

There is also the option of configuring the machine to be capable of making half pallets, as well as measuring it to make 20 or 40 boxes/minute.

All our palletisers have the option of a remote assistance system via Wi-Fi.

VIDEO

Related Searches

- Industrial robot

- Packing machine

- Automatic packing machine

- Articulated robot

- Packing machine for the food industry

- Palletizer

- Vacuum packing machine

- Layer palletizer

- Robotic palletizer

- Palletizing robot

- Case palletizer

- Transfer robot

- Cardboard box palletizer

- Depalletizer

- Palletizer for the packaging industry

- Compact palletizer

- Automatic depalletizer

- Pneumatic packing machine

- High-speed palletizer

- Layer depalletizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.