- Packing - Handling - Logistics

- Storage

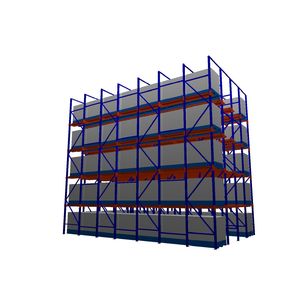

- Shuttle shelving

- iRacking Company

Shuttle rack system compactpalletfor cold storage

Add to favorites

Compare this product

Characteristics

- Inventory management

- shuttle

- Configuration

- compact

- Applications

- pallet, for cold storage

- Other characteristics

- electric

Description

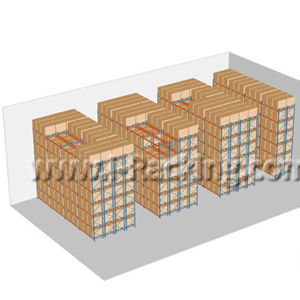

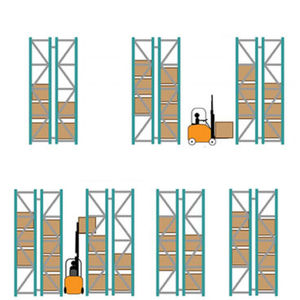

Pallet Shuttle Rack System is a compact storage system in which a shuttle, driven by an electric motor runs on rails inside the storage channels, replacing forklifts, considerably reducing operating times and enabling items to be grouped by channel rather than in complete lanes.

By removing the need for forklifts to enter the lanes, storage capacity is increased in terms of depth, the risk of accidents and damage to the racks is negligible, operator movements are optimized and warehouse operation is modernized and made more flexible.

It is an ideal solution for companies with a high volume of pallets per item and intensive loading and unloading activity.

Benifits:

• Greater diversification: each channel can be used to store a different item.

• Greater diversification: each channel can be used to store a different item.

• High productivity: increased flow of incoming and outgoing goods.

• Highly cost-effective, thanks to the reduction in operating costs.

• Decreased incidents and maintenance costs.

• Cold storage. It is ideal for warehouses where low temperatures are required, since it takes full advantage of the storage volume and reduces maneuvering times.

Catalogs

No catalogs are available for this product.

See all of iRacking Company‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.