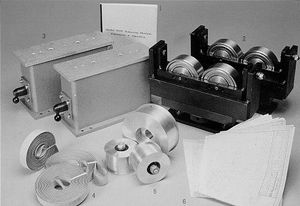

Horizontal balancing machine B140-280Kdynamiclarge

Add to favorites

Compare this product

Characteristics

- Orientation

- horizontal

- Type

- dynamic

- Other characteristics

- large

- Weight on rotor

280,000 lb

(127,005.9 kg)

Description

Performance Specifications

for

Model B140 Balancing Machine

127000 kg (280000 Pounds) Capacity

End Drive/Machining Type

Balancing Machine

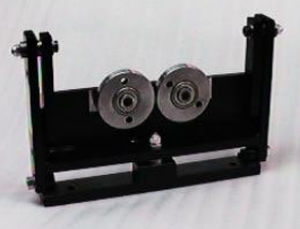

1.1.1 The Model B140 is a dynamic, horizontal axis, soft bearing balancing machine. It uses moving coil transducers to measure the motion of an unbalanced rotor on freely moving suspensions. The machine must be firmly mounted to a standard reinforced concrete floor, but does not require any special foundation. In order to provide an easy to use transportable mounting method, track clamps are provided to lock the pedestals and console to an existing railroad track or an optional prefabricated railroad track bed assembly. The Model B140 has an

End Drive console with a variable speed motor and multi-speed gearbox for efficient transfer of torque to the rotor. The End Drive system uses a cardan shaft (supplied) to spin the rotor. Adapters to attach the cardan shaft to the rotor are the customers’ responsibility. The use of a cardan shaft may require the use of electronic tooling compensation (a feature in the Model 295 instrument) to eliminate errors due to fit-up and/or unbalance in the adapter tooling.

The machine and instrument are easy to set up and use. The standard calibration method uses trial weights to calibrate the rotor to the balancing instrument for the most accurate possible unbalance readout.

Instrumentation

1.2.1 The standard balancing instrument is the Model 295 which has large digital display meters and shaft synchronous digital filters. Dynamic (Left/Right), Static and Couple unbalance can be displayed, individual workpiece setups can be stored and the balance results can be printed on an external printer.

Catalogs

No catalogs are available for this product.

See all of IRD Balancing‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.