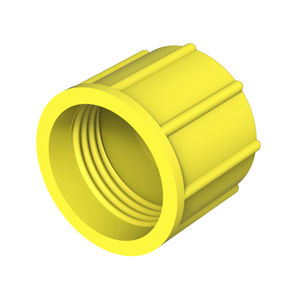

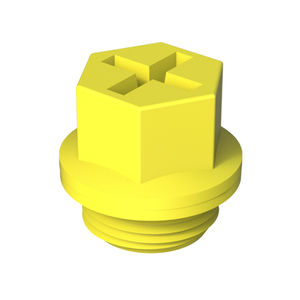

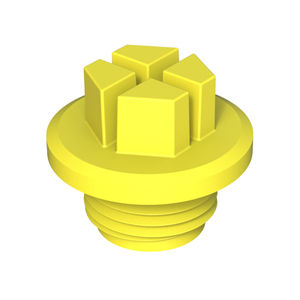

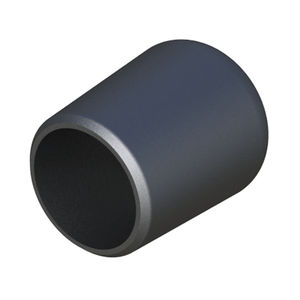

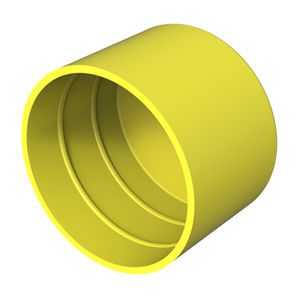

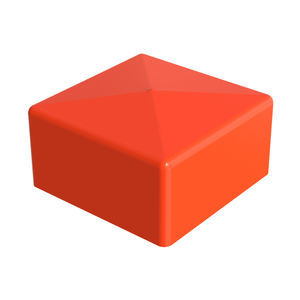

Rectangular cap VCREPVCmolded

Add to favorites

Compare this product

Characteristics

- Configuration

- rectangular

- Material

- PVC

- Other characteristics

- molded

Description

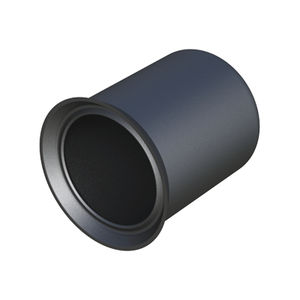

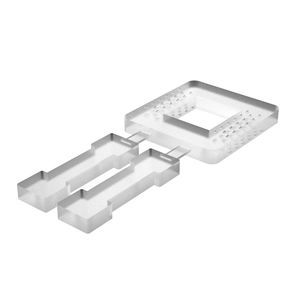

Dip Molding is the process carried out by means of a tank filled with cold liquid PVC where a mold with a multitude of figures is introduced at a higher temperature. When the PVC is fixed, the pieces are formed (different thicknesses are achieved by submerging it more or less times). Once molded, the mold is removed from the tank, and the pieces are treated, cooled down and removed from the mold. We produce a wide range of inside diameters with infinite possibilities of lengths, so if you don't find the desired size and / or design, please contact us .

The parts, manufactured in standard black color, do not require the addition of special additives to protect them from ultraviolet (UV) rays and are ideal if exposed to the elements .

Catalogs

No catalogs are available for this product.

See all of ISC PLASTIC PARTS‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.