The new drills provide an ultimate solution for drilling the most popular hole diameters in wind turbine parts such as blade bearings, tower flanges, yaw rings and planetary ring gears.

Planetary Ring Gear

Ring gears embrace the gearbox’s planetary gears, allowing them to transform low incoming speed to high outgoing speed.

Yaw Ring

The yaw system of wind turbines is the component responsible for the orientation of the wind turbine rotor towards the wind.

This is a mechanism that rotates the nacelle to face the changing wind direction. Made of alloy or bearing steel.

Blade Bearing

Adjusts the angle of the blades by rotating a bearing at the root of each blade.

The blade bearing enables control of the power and slows the rotor. Made of bearing steel.

Tower Flange

The vast majority of commercial wind turbines use tubular steel towers. Tower heights depend on rotor diameter and wind speed conditions of the site.

Their heights range from 50 meters for a 1 MW turbine to as high as 125 meters and more for very large turbines. The flange comprises a large scale of rolled steel which connects the tower’s conical links.

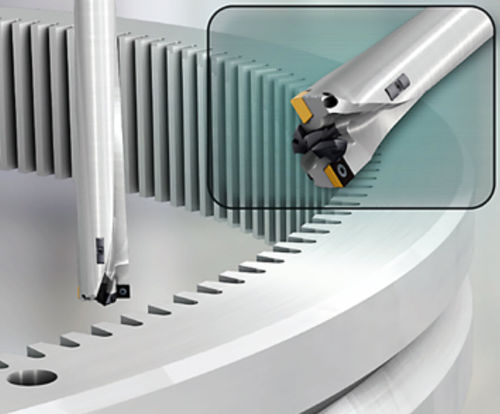

The drills feature a pilot SUMOCHAM drilling head and standard SOGT square precision ground inserts with a wiper in various sizes, made from IC808 SUMO TEC PVD coated grade.

This truly effective drill enables high feed drilling, providing high drilling rates, high accuracy and excellent surface finish.

High Productivity COMBI DRILL for Windmills

New COMBICHAM drilling line provides minimum cycle time and the most cost effective solution for this operation.

Features

2 effective cutting edges for high productivity

2 guide pads for improved stability during