Plastic profile polymercomposite materialresin

Add to favorites

Compare this product

Characteristics

- Material

- plastic, polymer, composite material, resin

- Configuration

- rectangular, tubular

- Applications

- industrial, construction

Description

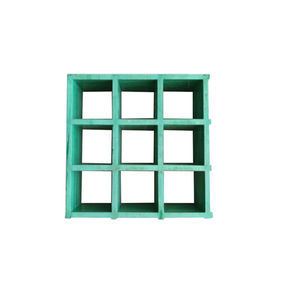

Cooling Tower FRP Pipe is produced by FRP material with Pultrusion Process. The thichness and diameter can been customized according to the request.

Cooling Tower FRP Pipe is widely used in the cooling tower( such as protective fence,handrails,ladders,supports,cable trays,pipe supports,construction of cooling towers,mobile towers,etc) and many other fields (such as the building materials, nursery stock support poles, tool handles, flag poles, tent poles, road marking poles and so on).

Cooling Tower FRP Pipe

Fiber reinforced plastic (FRP), also known as fiber reinforced polymer, is in fact a composite material constituting a polymer matrix blended with certain reinforcing materials, such as fibers. The fibers are generally basalt, carbon, glass or aramid; in certain cases asbestos, wood or paper can also be used.

Most of these plastics are formed through various molding processes wherein a mold or a tool is used to place the fiber pre-form, constituting dry fiber or fiber containing a specific proportion of resin. After ‘wetting’ dry fibers with resin, “curing” takes place, wherein the fibers and matrix assume the mold’s shape. In this stage, there is occasional application of heat and pressure. The different methods include compression molding, bladder molding, mandrel wrapping, autoclave, filament winding, and wet layup, amongst others.

The other exclusive properties of fiber reinforced plastics include commendable thermal insulation, structural integrity, and fire hardness along with UV radiation stability and resistance to chemicals and other corrosive materials.

Catalogs

No catalogs are available for this product.

See all of ISO9001‘s catalogsRelated Searches

- Profile

- Metal profile

- Aluminum profile

- Industrial profile

- Rectangular profile

- Construction profile

- Frame profile

- Polymer profile

- Round profile

- Flat profile

- Custom profile

- Steel profile

- Square profile

- Protection profile

- Pultruded profile

- Tubular profile

- Composite profile

- Vinyl profile

- Rod profile

- Composite material profile

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.