Resin profile steelroundrectangular

Add to favorites

Compare this product

Characteristics

- Material

- steel, resin

- Configuration

- rectangular, round, tubular

- Applications

- construction

- Other characteristics

- GRP

Description

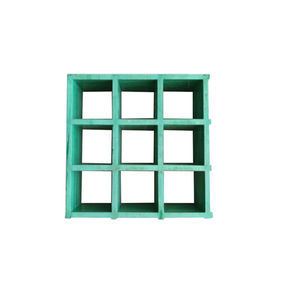

FRP Component, including the GRP pipe, it is high strength in lengthwise (LW) and crosswise (CW) and produced according to the relevant Europe standards.

They are used widely in domestic and overseas in cooling tower, power industries and any other proper construction. It could used as the structure and distribution pipes for the cooling tower industry.

GRP pipes's adantage is high temperature resistance, anti-corrosion, high strength, small specific gravity, low moisture absorption, small extension and good insulation,etc.

FRP Component

For the cooling tower usage, FRP component now instead of the steel component, since it's production time is shorter, anti-rust and high strenght. FRP components is widely used in the cooling towers as the structure and construction. It include the FRP tube, FRP channel, FRP handrail, FRP post and other customized FRP profile. All these FRP components were made by the pultrusion process.

During the pultrusion process,the raw material are pulled through a heated steel forming die using a continuous pulling device. when the reinforcements are saturated with the resin mixture in the resin bath and the wetted reinforcement package is wrapped in a surfacing veil. the completed package then goes into a performer that roughly forms the package into the appropriate shape to enter the heated die for curing. the die is the exact shape of the final part desired. upon exiting the die, the part is over 90% cured and solid. the length of the part required is pulled through the cutoff saw and the process is complete.

Catalogs

No catalogs are available for this product.

See all of ISO9001‘s catalogsRelated Searches

- Profile

- Metal profile

- Aluminum profile

- Industrial profile

- Rectangular profile

- Construction profile

- Frame profile

- Polymer profile

- Round profile

- Flat profile

- Custom profile

- Steel profile

- Square profile

- Protection profile

- Pultruded profile

- Tubular profile

- Composite profile

- Vinyl profile

- Rod profile

- Composite material profile

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.