- Environment - Health - Safety

- Cleaning and Hygiene

- Industrial vacuum cleaner

- ITALYVACUUM S.R.L.

- Products

- Catalogs

- News & Trends

- Exhibitions

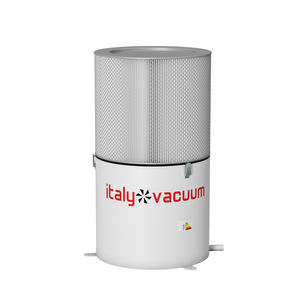

Industrial vacuum cleaner BLOW MISToil mistchipelectric

Add to favorites

Compare this product

Characteristics

- Domain

- industrial

- Substance vacuumed

- oil mist, chip

- Power source

- electric

- Configuration

- stationary

- Power

Min.: 4 kW

Max.: 24 kW

Description

Perfect combination of a vacuum cleaner designed for the division of chips and dust which, through special specific filters, is made perfectly compatible for the division of oil mist.

In order to meet the need to eliminate large quantities of oil-impregnated chips and related airborne mists that can cause serious health and safety problems, the blow mist model was designed.

Blow Mist, through a powerful cyclone of the suctioned material and a series of filters designed for this purpose, manages to completely eradicate these problems by eliminating all the related risks.

Required in sectors where you normally work 24h in order to never interrupt the workflow, they can be connected to more than one machine, and are also equipped at the base of the central unit with a rotary valve that continuously unloads the material onto a big bag or on a container equipped with wheels.

The special shape of the reinforced fans used in these units allow not only the suction of the material even from a considerable distance but also the partial or total breaking of long twisted shavings that are not easy to manage in order to make their collection easier.

Possibility of its use as a centralized system which reduces the distance between the vacuum cleaner and the point of application therefore allowing to express all its power without any load loss;

Technological and highly effective integrated cyclonic system as standard on each model with division of the air flows inside the aspirator which is calculated and optimized with the help of powerful dedicated software;

VIDEO

Catalogs

No catalogs are available for this product.

See all of ITALYVACUUM S.R.L.‘s catalogsRelated Searches

- Industrial dust extractor

- Electric dust extractor

- Dry dust extractor

- Mobile dust extractor

- Compact dust extractor

- Wet dust extractor

- Dust dust extractor

- Stainless steel dust extractor

- ATEX dust extractor

- Wheel-mounted dust extractor

- Steel dust extractor

- Safety vacuum cleaner

- Anti-static dust extractor

- Heavy-duty dust extractor

- Dust extractor with HEPA filter

- Stationary dust extractor

- Suction system

- Hazardous environment dust extractor

- Chip dust extractor

- Cyclone dust extractor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.