- Machine-tools

- Machine Tool Accessory

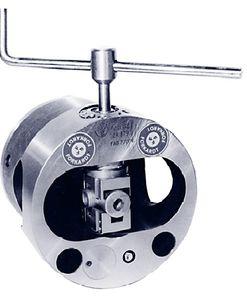

- Radial chuck

- ITW Workholding

Radial hydraulic chuck ZHRSTworkpiece

Add to favorites

Compare this product

Characteristics

- Other characteristics

- radial, workpiece

Description

The centrically clamping ZHSR indexing chuck was developed on the basis of the proven HSR console chuck design.

Console chucks offer a suitable and economical solution for many workpiece clamping applications.

For applications such as the machining of investment castings, pipe sockets, etc., centrically clamping indexing chucks are required because of the required accuracy of the finished contour to the clamping contour.

Our centrically clamping indexing chucks are also almost always used on pickup machines (vertical spindlers) where the chuck picks up the workpiece from an assembly line.

Centrically clamping FORKARDT indexing chucks generate the clamping force through two clamping pistons with wedge bars lying parallel to the axis and introduce them into the round base jaws.

Both base jaws are synchronized by a radial shaft. The part-turn actuator corresponds to the HSR design.

The centering accuracy is comparable with normal power chucks of the same size.

The indexing position control via dynamic pressure measurement is a direct query of the air pressure of the individual 90° positions.

The 45° positions can also be monitored so that the chuck can be used as an 8×45° swivel chuck.

Precise tilting via “M” commands

Indexing directly to the desired position

Stable, closed body

Direct support of the wedge bars in the body

Proven slide part-turn actuator

Light base jaws

High clamping force

No system imbalance in the indexing positions

Fastening of the clamping inserts from outside

Catalogs

No catalogs are available for this product.

See all of ITW Workholding‘s catalogsRelated Searches

- Chuck

- Milling chuck

- Collet chuck

- DIN chuck

- 3-jaw turning chuck

- High-speed chuck

- Workpiece clamping chuck

- Machining collet chuck

- Lathe turning chuck

- Precision collet chuck

- Modular chuck

- Machining turning chuck

- Quick-change chuck

- Manual turning chuck

- Milling collet chuck

- Precision turning chuck

- DIN collet chuck

- Through-hole turning chuck

- Radial chuck

- Manual tightening chuck

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.