- Metrology - Laboratory

- Inspection and Monitoring

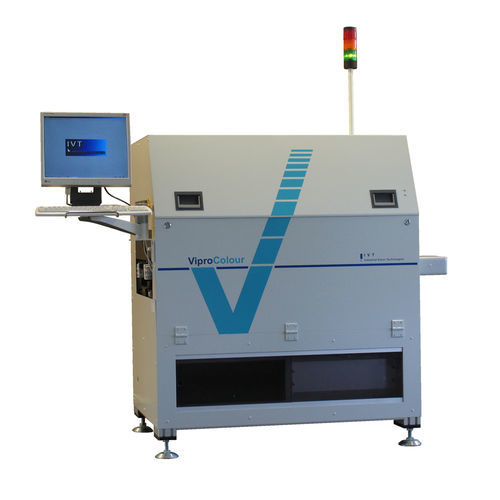

- Optical inspection system

- IVT Industrial Vision Technologies GmbH

Optical inspection system ViproColour Inlineautomaticsolderingfor production

Add to favorites

Compare this product

Characteristics

- Technology

- optical

- Operational mode

- automatic

- Type

- soldering

- Applications

- for production

- Configuration

- in-line

Description

The solder joint inspection system

ViproColour Inline is designed for high

volume and inline productions. However,

different methods of programming allow

an easy and fast setup of test programs

for different sizes of batches.

For small batches and prototyping

programming can be done fast and

easily by image comparison with a

Golden Board. A manual and an

automatic mode are available.

In the manual mode the Golden Board

and the production board appear

alternately at the computer monitor.

Differences in the images (defects) will

fast be recognised by the operator.

In the automatic mode the areas to be

tested have to be predetermined. When

using a bare board or a printed board,

these test areas are created automatic-

ally. All of these test areas are later

compared with the golden board. A

report will be generated during the test.

If a Golden Board is not available, a

normal production board can be used,

with all the variations in process quality.

These boards are not perfect

references, but the programming is fast

and easy.

If the batch size is bigger or a higher

level of test depth and a lower quantity

of pseudo defects are required, the

programming with CAD-data is advised.

The comprehensive component library,

which is included, simplifies program-

ming. The component library provides

all parameters which can be modified by

the operator. Additionally, new customer

specific libraries can be set up.

Catalogs

ViproColour Inline

2 Pages

Other IVT Industrial Vision Technologies GmbH products

Products

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.