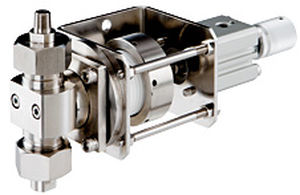

Bellows pump FLPfor chemicalspneumaticstationary

Add to favorites

Compare this product

Characteristics

- Technology

- bellows

- Fluid

- for chemicals

- Operation

- pneumatic

- Mobility

- stationary

- Domain

- industrial

- Applications

- discharge, for control

- Other characteristics

- built-in

- Flow

50 l/min, 92 l/min

(13.2086 us gal/min, 24.30383 us gal/min)- Pressure

0.3 MPa, 0.4 MPa, 0.5 MPa

- Fluid temperature

Max.: 180 °C

(356 °F)Min.: 5 °C

(41 °F)

Description

Low Pulsation

The position of the bellows is constantly monitored via the laser displacement sensors and proximity switches. The pump itself reduces pulsation without any additional equipment because the controller determines the appropriate amount of phase shift required to move the bellows left and right via an electromagnetic valve.

Reduced Sensors

External sensors are not needed since the pumps phase control of the bellows depends entirely on signals from the laser and proximity sensors included in the design.

High Pressure

The optimum bellows movement increases sustained pressure capability, maintaining stable discharge capacity and pressure under frequent load changes, especially in single wafer processing.

Safe Design

A welded bellows structure prevents liquid leakage. Even if the bellows is damaged, the built-in leak sensors will detect and provide feedback to ensure safe operation.

Catalogs

No catalogs are available for this product.

See all of IWAKI‘s catalogsRelated Searches

- Pump

- Industrial pump

- Pump with electric motor

- Stationary pump

- Clear water pump

- Centrifugal pump

- Self-priming pump

- Chemical pump

- Stainless steel pump

- Lubricant pump

- Transfer pump

- Chemistry pump

- Suction pump

- Compact pump

- Lubricating oil pump

- Diaphragm pump

- Air-driven pump

- Flow pump

- Mechanically-actuated pump

- Impeller pump

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.