Automatic filling line TFS 80-4/-6/-8for creamfor tubescosmetic cream

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Container type

- for cream, for tubes

- Product applications

- cosmetic cream, for food, for pasty products, for paint, for viscous products, for adhesive materials

- Number of heads

- multi-head

- Other characteristics

- PLC-controlled

- Throughput

340 p/min, 510 p/min, 750 p/min

- Volume

Max.: 220 ml

(7.4 US fl oz)Min.: 2 ml

(0.1 US fl oz)

Description

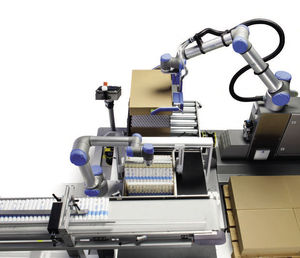

Highest performance and reliability, intelligent controls for optimal process cycles and outstanding process safety have turned IWK into the market leader with automatic tube filling machines for medium and upper outputs.

The new tube filling line TFS 80-8 guarantees complete weight checking and control, thus reducing tube overfilling significantly. With a fill rate of 750 tubes per minute, the TFS 80-8 is faster than any other tube filling machine in the world.

A wide range of options and additional equipment such as IWKs tube feeding systems, and seamless integration of downstream equipment guarantees that today’s most sophisticated tube packaging demands are met.

Benefits:

- Short changeover times due to quick acting couplings

- Designed to meet GMP standards, simple operation and optimal accessibility

- Optimal process cycles and outstanding process safety

- Allowed time for the work processes regardless of the cycle time of the machine

- Compact construction

- Lesser and simplified setup operations, best flexibility and reliability

- Modular design concepts for diverse tube closing systems and add-on components

APPLICATIONS

Products:

Tooth paste, adhesive cream for dentures, ointment, cream, gel, shampoo, hair-dye, adhesives, paint, silicon, ketchup, mayonnaise, mustard

Catalogs

TFS 80-4/-6/-8

8 Pages

Related Searches

- Automatic filler

- Food product filling machine

- Volumetric filler

- Multi-head filler

- Filler for the pharmaceutical industry

- PLC-controlled filler

- Cartoner

- High-speed filler

- Sauce filler

- Depalletizer

- Horizontal cartoner

- Filler with 2 heads

- Pasty product filler

- Viscous product filling machine

- Filler and sealer

- Viscous product filler

- Automatic filler and sealer

- Cartoner for the pharmaceutical industry

- Aseptic filling system

- Cosmetic cream filling line

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.