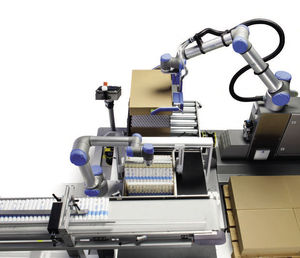

Tube feeder COBOT TZCgripperroboticfor packaging lines

Add to favorites

Compare this product

Characteristics

- Type

- gripper

- Operating mode

- robotic

- Product applications

- for tubes

- Other characteristics

- for packaging lines

Description

CoBot Systems greatly increase the cost-efficiency of packaging lines overall through automatic supply to the filling line. They correspond to current Global safety norms, and can be used immediately without any additional safety and monitoring systems. In addition, retrofitting in installed equipment is not only possible but also straight-forward. Depending on utilization, the ROI period for an IWK CoBot system is just 12 months.

CoBot-supported IWK TZC tube infeed: The robot arm transfers the empty tubes to the removal area, while lateral guide strips ensure precise positioning. There is no protective enclosure on the IWK TZC, and as a result the machine operator is able to manually correct the tube positioning immediately if needed. Changing a format part requires just a small number of hand movements, and generally only takes a few minutes. The parameters can be stored in each case, and accessed later as a complete setup. The controls of the CoBot system are fully integrated into IWK equipment, and can be conveniently operated without any programming knowledge using the IWK HMI operator panel.

Catalogs

No catalogs are available for this product.

See all of IWK‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.