- Products

- Catalogs

- News & Trends

- Exhibitions

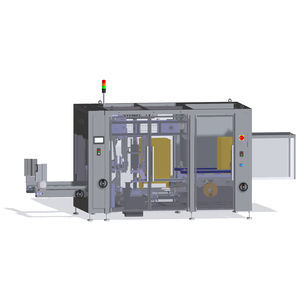

Automatic tray former ITFhot-melt glue

Add to favorites

Compare this product

Characteristics

- Operating mode

- automatic

- Type

- hot-melt glue

Description

The iXAPACK GLOBAL automated Tray Former is an equipment that completes our range of overwrapping solutions amongst cartoning, case packing, palletizing systems… This Tray Erector can handle up to 30 trays per minute, ideal for low volume productions.

Once flat blanks are loaded in the magazine, trays are erected, sealed via Hotmelt gluing system and then ready for output palletizing or manual handling.

This Tray Former is modular and can be adapted as per your layout, on the front, right or left side of the machine. Downstream, trays can be headed to a manual or robotized loading station.

Stackable trays (with or without corners), four-glued corner trays… this equipment is geared up for multi-format production for greater flexibility. Another great advantage is the quick format changes are made via an intuitive HMI, where the different settings are available.

Robust and reliable machine not requiring loads of maintenance, this automated Tray Erector is easy-to-use, ergonomic within a small footprint, enabling an easy integration in your production lines.

A manufacturing process entirely handled in-house

From your initial request to final commissioning on your site, including after-sales service, you can rely on iXAPACK GLOBAL’s reactivity to assist you throughout the entire process.

Indeed, your equipment’s design and manufacturing are entirely carried out in our R&D Department, located on one production site close to Nantes International Airport. A single contact for your entire project, for a reactive follow-up!

Catalogs

No catalogs are available for this product.

See all of iXAPACK GLOBAL‘s catalogsRelated Searches

- Packing machine

- Automatic packing machine

- Bagging machine

- Automatic labelling machine

- Automatic bagging machine

- Packing machine for the food industry

- FFS bagging machine

- Palletizer

- Bagging machine for the food industry

- Film packing machine

- Horizontal bagging machine

- Side labelling machine

- Labeler for the cosmetics industry

- Complete packaging line

- Automatic palletizer

- Top labelling machine

- Case packer

- Packaging machine for the food industry

- Layer palletizer

- Robotic palletizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.