- Hydraulics - Pneumatics

- Pump

- Plunger pump

- JAECO Fluid Systems

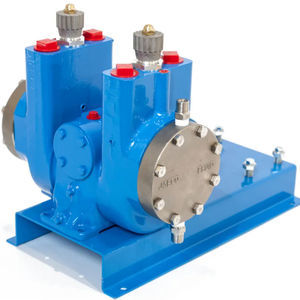

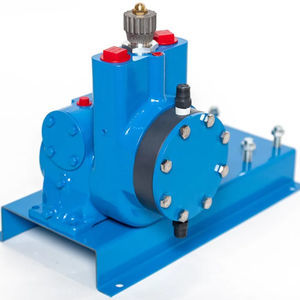

Plunger pump 519-Duplex serieswaterhydraulically-operatedstationary

Add to favorites

Compare this product

Characteristics

- Technology

- plunger

- Fluid

- water

- Operation

- hydraulically-operated

- Mobility

- stationary

- Domain

- industrial

- Applications

- metering

- Material

- stainless steel, PTFE

- Voltage

- 230 V, 460 V, 115 V

- Other characteristics

- heavy-duty, adjustable, flow, actuated

- Flow

Min.: 0.039 m³/h

(1.37727 ft³/h)Max.: 0.246 m³/h

(8.68741 ft³/h)

Description

Jaeco FRAM 519 diaphragm pumps are hydraulically actuated metering pumps designed for accurate, completely leak-proof metering of difficult-to-handle liquids. The Fram 519 duplex has flow rates from 10.4 GPH to 56 GPH with a maximum pressure of 500 PSI. Separate chambers for hydraulic fluid and gear lubricant make possible the use of the best medium for hydraulic diaphragm pulsing and the best medium for gear lubrication. The results are better pump performance and longer pump life. This diaphragm pump is duplex, includes a 1/3 horsepower motor, and 316 stainless steel liquid end.

Simplex pump but can be field converted to a duplex

Diaphragm material = Teflon (PTFE)

Plunger diameter = 13/16″

Liquid End = 316 Stainless Steel (call for other materials)

Motor options:

Single Phase 7235 – 1/3 HP, TEFC, 1725 RPM, 1/60Hz, 115-230 Volt

Three Phase 7245 – 1/3 HP, TEFC, 1725 RPM 3/60 HZ, 230-460 Volt

Flow rate measured in Gallons Per Hour (GPH)

Patented, heavy-duty gear reducer system for superior performance.

Hydraulically actuated diaphragm minimizes diaphragm fatigue.

A built-in hydraulic relief valve protects the pump.

Stroke rate easily automated using a variable-speed drive.

Capacity is adjustable while the pump is running or idle.

Capacity is adjustable for a turn-down ratio of 10:1.

Easy-to-read stroke length adjustment dial.

Available with or without a motor.

No plunger seals to leak or replace.

Oil bath gear lubrication eliminates the maintenance required by packing grease or auxiliary oil systems.

Catalogs

Jaeco CutSheet Fram

2 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.