- Products

- Catalogs

- News & Trends

- Exhibitions

Programming software NX Progressive Die Designdesignautomationprocess

Add to favorites

Compare this product

Characteristics

- Function

- programming, design, automation

- Applications

- process

- Other characteristics

- NX

Description

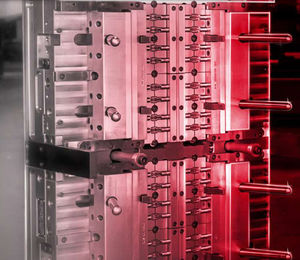

NX Progressive Die Design offers a new type of solution for the design of progressive dies. Manufacturers not only shorten their delivery times by using this module, but also optimise and automate their tool design processes. From the design to tool validation - NX Progressive Die Design is a comprehensive solution for manufacturers of progressive dies.

Fewer errors in tool design

Automation of manufacturing processes

Reduction in CNC programming time

Centralisation and control of the design information

Clearly-structured process development

The standard NX functions support you in the efficient design of sheet metal parts. Using bend tables, you can create parts with pre-bends and overbends.

The handling of the bent part through to the untreated strip enables the complete process to be illustrated. The associativity between the part design and the progressive die becomes a matter of course with the NX software. Internal factory standards and their reuse can be recorded and used and optimised through to production.

Specification of strip details and the progress of the design phase by means of an optimised workflow

Efficient design and visualisation of moulding and die cutting tools

Integrated library for standard parts

Provision of information for an automated manufacturing process

Dynamic collision recognition by means of motion simulation

Related Searches

- Automation software solution

- Management software solution

- Process software solution

- Control software solution

- Computer-aided design software

- Online software

- Design software solution

- 3D software solution

- Interface software

- Industrial software solution

- Quality software

- Simulation software

- Automated software

- Programming software

- Development software

- Machine software

- EDM software

- Creation software

- CAM software

- Inspection software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.