- Products

- Catalogs

- News & Trends

- Exhibitions

Process software NX Additive Manufacturingprinting3D

Add to favorites

Compare this product

Characteristics

- Applications

- process, printing

- Type

- 3D

Description

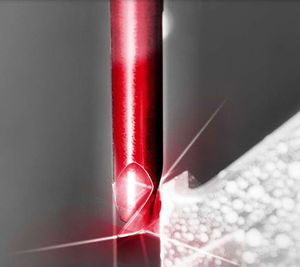

3D printing is rapidly developing into another efficiency-increasing technology and is changing the industry. Additive manufacturing opens up new possibilities for the manufacturing of components, as well as more efficient use of materials by optimising the blanks.

Manufacture of new, more efficient component shapes with a wide variety of materials (including metal)

Repair of expensive components, which has previously been too costly or impossible

Reduced production costs

Shorter lead times

Increase in the efficiency of the manufacturing process with optimised blank shapes and new manufacturing processes

This hybrid expansion of manufacturing represents the reversion from erosive (cutting) manufacturing to additive manufacturing. By using layer-by-layer material deposition, component shapes can be created that would not be possible using cutting or casting manufacturing alone. The combination of these manufacturing processes (hybrid form) firstly enables new possibilities for the manufacturing of components and secondly the efficient use of materials by optimising blanks.

With its software product portfolio, Siemens is leading the way in this digital technology and its combination with other manufacturing processes. It offers design, simulation and manufacturing software solutions for powder-bed-based 3D printing.

Different processes can be used (powder bed, 3D laser etc.)

Automated creation of supporting geometries

Nesting functions

Quick and easy part repair

New component shapes and more efficient blank shapes

Hybrid manufacturing (additive and cutting)

VIDEO

Other JANUS ENGINEERING products

CAM - Computer Aided Manufacturing

Related Searches

- Automation software solution

- Management software solution

- Process software solution

- Computer-aided design software

- Control software solution

- Online software

- Design software solution

- 3D software solution

- Interface software

- Industrial software solution

- Quality software

- Simulation software

- Programming software

- Automated software

- Development software

- Machine software

- EDM software

- Creation software

- CAM software

- Inspection software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.