- Robotics - Automation - Industrial IT

- Industrial Software

- CAD software

- JANUS ENGINEERING

- Products

- Catalogs

- News & Trends

- Exhibitions

Programming software VoluTurnCAD

Add to favorites

Compare this product

Characteristics

- Function

- programming, CAD

Description

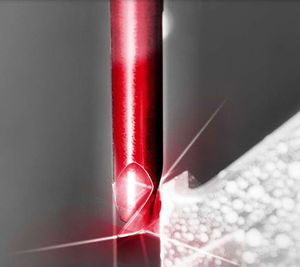

Gone are the days when tool paths were laboriously created using CAD geometries such as lines and arcs. VoluTurn enables you to create more efficient, associative tool paths in seconds, while completely preventing collisions.

Increased productivity thanks to shorter cycle times

Dramatically reduced programming time for complex components

Increased service life of the tool – elimination of overloading and dwell time

Reduced machining loads – material entry and exit is always smooth, circular and tangential

This software module, which comes from the USA, is an outstanding addition to NX CAM. It is completely integrated into NX and offers a new kind of efficient tool path technology for turning. This is based on unidirectional and bidirectional cut patterns with constant or variable depth, in order to make optimum use of the cutting inserts while avoiding the formation of notches.

VoluTurn is particularly effective for the components used most frequently in the energy industry, i.e. for parts with complex geometries that are turned from materials that are difficult to machine. Industries in which these or similar challenges are faced, particularly stand to benefit from VoluTurn.

Automatic collision prevention even with full mountings

Efficient repositioning between cuts

Entry and exit arcs are automatically calculated for optimum performance and to minimise operational wear

Interim withdrawal options, based on time, distance or number of passes, to check, index or change inserts

Uniform material removal and tool load across the whole pathway

VIDEO

Other JANUS ENGINEERING products

CAM - Computer Aided Manufacturing

Related Searches

- Automation software solution

- Management software solution

- Process software solution

- Computer-aided design software

- Control software solution

- Online software

- Design software solution

- 3D software solution

- Interface software

- Industrial software solution

- Quality software

- Simulation software

- Programming software

- Automated software

- Development software

- Machine software

- EDM software

- Creation software

- CAM software

- Inspection software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.