- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Elastomer coupling S-Flex torsionally flexiblecurved-tooth geargear

Add to favorites

Compare this product

Characteristics

- Type

- elastomer, torsionally flexible, curved-tooth gear, gear

- Product applications

- for shafts, transmission, for pump, for marine applications, for paper machines, for agitators, for railway applications, for servo motors, engine, for the cement industry, machines, for compressors, for rolling mills, for printing machines, for the textile industry, for mechanical power transmission, for excavators, for mixers, for the food industry, for conveyor, for gears, for presses, for wind turbine, for the packaging industry, industrial

- Construction

- compact, shaft-hub

- Performance

- maintenance-free, low noise and vibration, non-lubricated

- Other characteristics

- misalignment correction, compensating, anti-vibration, with high torsional flexibility

- Installation system

- flange

- Torque

Min.: 6.78 Nm

(5.0007 ft.lb)Max.: 8,189 Nm

(6,039.8964 ft.lb)

Description

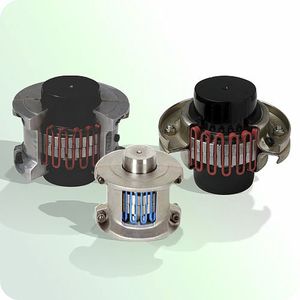

Continue to benefit from the characteristics of the S-Flex coupling but for 3 times longer! The new EPDM coupling sleeve element lasts at least 3 times as long as the previous design, saving you valuable downtime opportunity costs and maintenance costs.

» Easy to Install

» Maintenance Free

» No Lubrication

» Dampens Vibration and Controls Shock

» Torsionally Soft

» Double Engagement

The new material also provides at least 30% increased torque rating and allows for product downsize in 50% of applications creating an average cost saving of 23 - 33% for sleeve element replacement.

Extensive testing performed by the R&D department compared the new and improved EPDM S-Flex Endurance sleeve element material to the previous design and competitor’s similar style couplings. Ultimately the new EPDM S-Flex Endurance material met or exceeded performance in every testing category. Note the performance improvements are for the EPDM material only. The Neoprene and Hytrel® types remain unchanged.

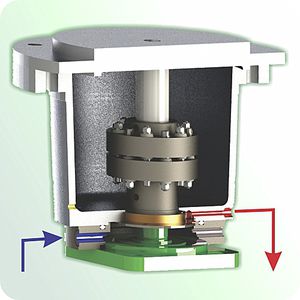

The S–Flex (flexible sleeve) coupling design is comprised of three parts. Two flanges with internal teeth engage an elastomeric flexible sleeve with external teeth. Each flange is attached to the respective shaft of the driver and driven and torque is transmitted across the flanges through the sleeve. Misalignment and torsional shock loads are absorbed by shear deflection in the sleeve.

The shear characteristic of the S–Flex coupling is very well suited to absorb impact loads. The S–Flex coupling from jbj Techniques offers combinations of flanges and sleeves which can be assembled to suit your specific application.

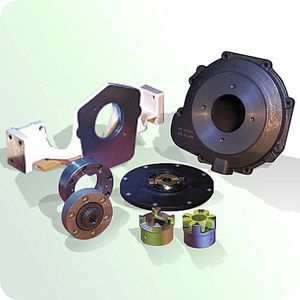

Other jbj Techniques Limited products

bellhousings & couplings for mechanical power transmission

Related Searches

- Planetary gearbox

- Coaxial gearbox

- Right angle gearbox

- Jbj-Techniques Limited flexible coupling

- Gear train gearbox

- Jbj-Techniques Limited shaft coupling

- Jbj-Techniques Limited friction brake

- Solid-shaft gearbox

- Hollow-shaft gearbox

- Industrial gear reducer

- Transmission gearbox

- Jbj-Techniques Limited flange coupling

- Multi-stage gearbox

- Single-stage gearbox

- Two-stage gearbox

- Machine gearbox

- Torque shaft coupling

- High-performance gearbox

- Jbj-Techniques Limited spring brake

- Electric motor gearbox

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.