- Power Transmission - Mechanical components

- Mechanical Transmission

- Gear coupling

- jbj Techniques Limited

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

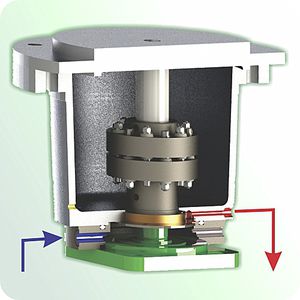

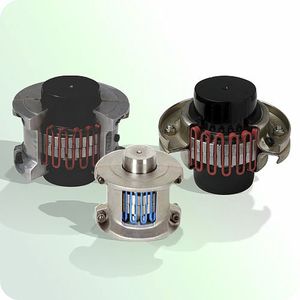

Gear coupling torsionally rigidfor shaftstransmission

Add to favorites

Compare this product

Characteristics

- Type

- gear, torsionally rigid

- Product applications

- for shafts, transmission, for pump, for paper machines, for presses, machines, for marine applications, for mechanical power transmission, for conveyor, for the cement industry, for railway applications, for hoisting machinery, for the aerospace industry, for rolling mills, generator, gearbox, for mixers, for agitators, engine, for wind turbine, for gears, for the textile industry, for chemical applications, for compressors, for excavators, for servo motors, for the food industry, for machine tools, for railway vehicles, for printing machines, for lifting equipment, for the packaging industry, industrial

- Construction

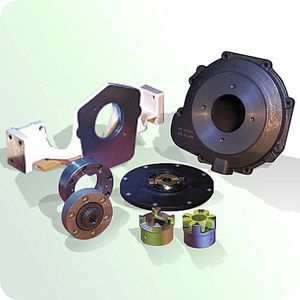

- shaft-hub, large-size, with spacer, with braking wheel

- Performance

- high-performance, high-speed, high load capacity, heavy-duty

- Other characteristics

- torque, ATEX, explosion-proof, disassemblable, for explosive areas, flameproof

- Installation system

- flange, sleeve

- Torque

Min.: 192 Nm

(141.6119 ft.lb)Max.: 161,003 Nm

(118,749.7187 ft.lb)- Rotational speed

Min.: 2,000 rpm

(12,566.37 rad.min-1)Max.: 9,000 rpm

(56,548.67 rad.min-1)

Description

Gear-couplings are the foremost coupling type. They can do things that many other coupling types are unable to perform, or that need expensive modifications and de-rating to function. Gear couplings have the highest power density, offer more variations, a wider size, torque, and bore capacity than any other coupling type. They are easily modified for shear pin service, floating shaft type, vertical applications, electrical isolation, limited end float, and can have a brake drum or disc added. While some features may be available on other couplings, it is typically easier and cost effective to modify a gear coupling. With all these advantages, the gear coupling is used on more applications versus the nearest competing coupling type.

Factors Affecting Selection

The following is a list of the information necessary to assist in making a coupling selection.

Not all of these items will come into play in all selection processes.

These items include, but are not limited to:

» Application details

» Type of motor and driven equipment

» Motor horsepower or KW

» Operating/coupling speed

» Shaft sizes and separation

» Space and size constraints

» Environment (temperature, chemicals, etc)

» Balance requirements

» Special modifications

For calculations and steps in the selecting the correct sized coupling please see www.jbj.co.uk/all-steel-gear-couplings.html

VIDEO

Catalogs

No catalogs are available for this product.

See all of jbj Techniques Limited‘s catalogsOther jbj Techniques Limited products

bellhousings & couplings for mechanical power transmission

Related Searches

- Planetary gearbox

- Coaxial gearbox

- Right angle gearbox

- Jbj-Techniques Limited flexible coupling

- Gear train gearbox

- Jbj-Techniques Limited shaft coupling

- Jbj-Techniques Limited friction brake

- Solid-shaft gearbox

- Hollow-shaft gearbox

- Industrial gear reducer

- Transmission gearbox

- Jbj-Techniques Limited flange coupling

- Multi-stage gearbox

- Single-stage gearbox

- Two-stage gearbox

- Machine gearbox

- Torque shaft coupling

- High-performance gearbox

- Jbj-Techniques Limited spring brake

- Electric motor gearbox

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.