- Hydraulics - Pneumatics

- Pump

- Cartridge pump

- jbj Techniques Limited

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

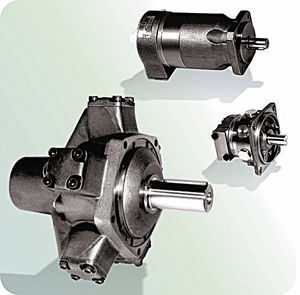

Cartridge pump rotary vanecentrifugalindustrial

Add to favorites

Compare this product

Characteristics

- Technology

- cartridge, rotary vane, centrifugal

- Domain

- industrial

- Applications

- replacement

- Other characteristics

- radial

- Flow

10 l/min, 227 l/min, 385 l/min

(2.64172 us gal/min, 59.96706 us gal/min, 101.70624 us gal/min)- Pressure

7 bar

(101.526 psi)- Power

27 kW, 126 kW, 328 kW

(36.71 hp, 171.31 hp, 445.96 hp)

Description

All the components subject to wear are contained in a cartridge unit that can be easily removed for inspection and/or replacement without disconnecting the pump from the circuit, drastically reducing expensive machine down time.

The cartridge contains a rotor, vanes and inserts, a cam ring and two covers.

During operation the rotor is driven by a splined shaft coupled to the drive unit. As the rotation speed increases, centrifugal forces, in combination with the pressure generated behind the vanes, push the vanes outwards, where they follow the profile of the cam of the ring with a sufficient contact pressure to ensure adequate hydraulic sealing.

The two opposed pumping chambers formed by the elliptical profile of the cam cancel out radial loads on the shaft bearings, thereby giving them extremely long lifetimes.

basic components of vane pump replaceable cartridge

The versatility of the BV series pumps enables them to meet the requirements of the most varied industrial applications. In fact, as well as their proven high reliability and excellent volumetric efficiency in all working conditions, they operate with particularly low noise levels.

This is made possible by the special profile of the cam ring and the use of a 12 vane rotor that reduces the amplitude of the supply pressure pulses, thereby reducing induced vibrations.

Catalogs

No catalogs are available for this product.

See all of jbj Techniques Limited‘s catalogsOther jbj Techniques Limited products

Hydraulic pumps & motors

Related Searches

- Pump

- Industrial pump

- Centrifugal pump

- Jbj-Techniques Limited hydraulic pump

- Radial pump

- Jbj-Techniques Limited hydraulic gear pump

- Hydraulic pump for industrial applications

- Jbj-Techniques Limited oil hydraulic pump

- Jbj-Techniques Limited low-noise hydraulic pump

- Jbj-Techniques Limited high-efficiency hydraulic pump

- Rotary vane pump

- Replacement pump

- Cartridge pump

- Jbj-Techniques Limited axial hydraulic pump

- Vehicle hydraulic pump

- High-performance hydraulic pump

- Hydraulic motor hydraulic pump

- Multi-stage hydraulic pump

- Two-stage hydraulic pump

- Hydraulic piston hydraulic pump

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.