- Hydraulics - Pneumatics

- Filter and Separator

- Threaded breather

- jbj Techniques Limited

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Hygroscopic breather threaded

Add to favorites

Compare this product

Characteristics

- Technology

- hygroscopic

- Mounting

- threaded

Description

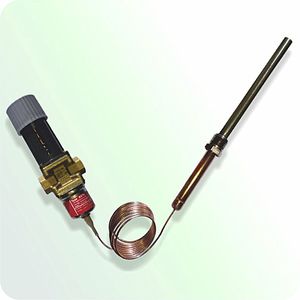

Remove moisture and particles before entry to the system.

Moisture and particle accumulation are major factors of oil contamination in industrial equipment. Neglected, these detriments restrict equipment efficiency, causing machine downtime and significant expense in replacement oil, parts and repair labour.

Hygroscopic breathers incorporate a proven, field tested design. They prevent water and contaminates from entering fluid reservoirs as differential pressures occur through thermal expansion and contraction of the fluid, or during the filling or emptying process.

Manufactured with a hygroscopic agent, they have the capability to extract water vapour from the air as it is drawn through the unit. Accompanying solid particles are then removed by a patented polyester fabric filter, allowing only clean, dry air to enter the system.

Change To Our Hygroscopic Breathers For Maximum Machine Performance.

These hygroscopic breather elements are state-of-the-art in design and function and are industry’s best choice for assuring maximum machine performance.

Cost saving benefits:

» Elimination of water contaminated oil which prevents additive stripping.

» Elimination of rust forming due to condensation.

» Elimination of sludge deposits.

» Less abrasive particles, to prolong machine operating life.

» Longer oil and oil filter life.

Catalogs

No catalogs are available for this product.

See all of jbj Techniques Limited‘s catalogsOther jbj Techniques Limited products

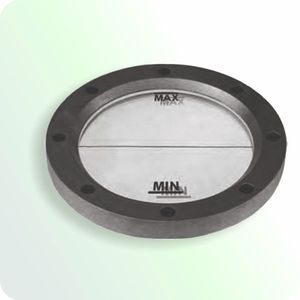

Fluid reservoirs & level indicators

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.