- Power Transmission - Mechanical components

- Mechanical Transmission

- Friction brake

- jbj Techniques Limited

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

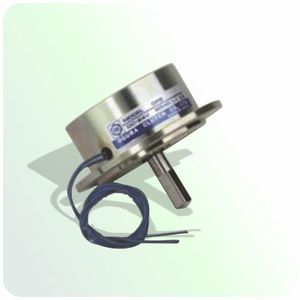

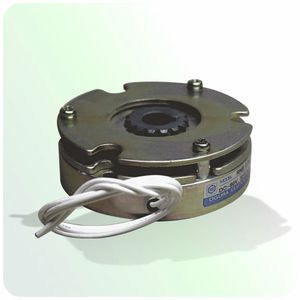

Friction brake PMB serieselectromagneticpermanent magnetzero-backlash

Add to favorites

Compare this product

Characteristics

- Type

- friction

- Operation

- electromagnetic

- Other characteristics

- permanent magnet, zero-backlash

- Torque

Max.: 30 Nm

(22.1269 ft.lb)Min.: 0.4 Nm

(0.295 ft.lb)

Description

Permanent magnet brake designed for industrial and mobile applications. Brake force is produced via magnets which reduces both size and weight of brake versus spring applied brakes. Armature is mounted via springs which eliminates backlash. Standard brakes can accommodate temperatures up to 140deg C. Brakes can be tuned to provide a controlled stop. Output assemblies easily modified to fit your application.

UL and CSA Recognized as a component for use in motion control systems. Approved in accordance with UL508, 17th edition and CSAC 22.2 No. 14-13, 12th edition.

High Torque Compact Design.

Because permanent magnets are used versus springs, the overall size of the brakes is smaller for a given torque size. Because the brakes are smaller, their weight is also less, which can be an advantage in some applications.

Controlled Stop.

Since torque is directly controlled by flux, a brake can be tuned to provide a softer stop in an application versus having full torque applied.

Easily Customized For Your Application.

Both the mounting flange and the output hub and armature assembly can be easily modified to fit your existing application.

Zero Backlash; The PMB Series of Brakes have a spring mounted armature, which eliminates backlash in the brake.

No Drag Torque; When brakes are released, an airgap is present which completely releases the armature resulting in zero drag.

High Operating Temperatures; The standard magnetic material used in the brakes can accommodate temperatures up to 140 degrees celsius. If an application requires it, special material is also available on some sizes to accommodate higher temperatures.

Other jbj Techniques Limited products

Electromagnetic clutches and brakes

Related Searches

- Planetary gearbox

- Coaxial gearbox

- Right angle gearbox

- Jbj-Techniques Limited flexible coupling

- Gear train gearbox

- Jbj-Techniques Limited shaft coupling

- Jbj-Techniques Limited friction brake

- Solid-shaft gearbox

- Hollow-shaft gearbox

- Industrial gear reducer

- Transmission gearbox

- Jbj-Techniques Limited flange coupling

- Multi-stage gearbox

- Single-stage gearbox

- Two-stage gearbox

- Machine gearbox

- Torque shaft coupling

- High-performance gearbox

- Jbj-Techniques Limited spring brake

- Electric motor gearbox

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.