- Power Transmission - Mechanical components

- Mechanical Transmission

- Hydrodynamic coupling

- jbj Techniques Limited

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Fluid coupling FLUDEX®for shaftfor machinesmisalignment correction

Add to favorites

Compare this product

Characteristics

- Type

- fluid

- Product applications

- for shaft, for machines

- Other characteristics

- misalignment correction

- Rotational speed

Min.: 600 rpm

(3,769.91 rad.min-1)Max.: 3,550 rpm

(22,305.31 rad.min-1)

Description

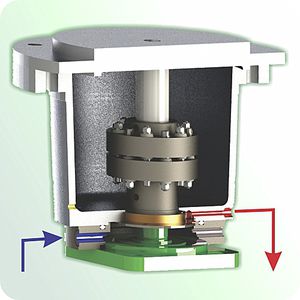

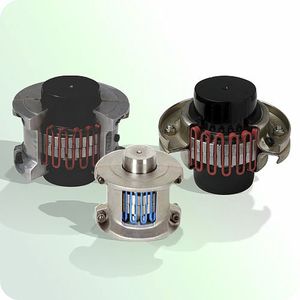

Hydrodynamic fluid couplings operate on the Fottinger principle. FLUDEX® couplings limit starting and maximum torque in the drive train and, through the property of rotational slip, serve as an aid to starting the motor, as overload protection in the event of fault and for isolating torsional vibration. To compensate for shaft misalignment, the FLUDEX coupling is combined with a displacement coupling e.g. of the N-EUPEX type.

The coupling parts on the input and output sides are not mechanically connected to each other. Output is transmitted via the oil filling which rotates in the coupling and is conducted over radially arranged blades. FLUDEX couplings limit starting and maximum torque in the drive train and, through the property of rotational slip, serve as an aid to starting the motor, as overload protection in the event of fault and for isolating torsional vibration.

When large masses are started up, the drive train is accelerated only at the torque determined by the coupling characteristic. The starting operation is spread over time, the driven machine started softly and smoothly. In the case of special operating conditions, such as overload or blocking of the driven machine, the FLUDEX coupling limits the maximum torque load and prevents the inert effect of the rotating motor mass on the drive train. The coupling then acts as a load-holding safety clutch until the drive is shut off by the motor control or coupling monitoring system. The FLUDEX coupling further acts as a means of decoupling during torsional vibration excitation.

https://www.jbj.co.uk/e-publications/FLUDEX-hydrodynamic-fluid-couplings-available-from-jbj-Techniques-Limited/index.html

Other jbj Techniques Limited products

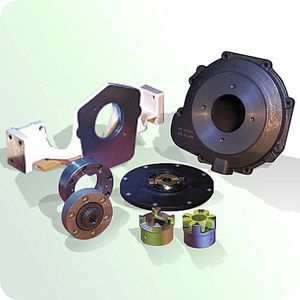

bellhousings & couplings for mechanical power transmission

Related Searches

- Planetary gearbox

- Coaxial gearbox

- Right angle gearbox

- Jbj-Techniques Limited flexible coupling

- Gear train gearbox

- Jbj-Techniques Limited shaft coupling

- Jbj-Techniques Limited friction brake

- Solid-shaft gearbox

- Hollow-shaft gearbox

- Industrial gear reducer

- Transmission gearbox

- Jbj-Techniques Limited flange coupling

- Multi-stage gearbox

- Single-stage gearbox

- Two-stage gearbox

- Machine gearbox

- Torque shaft coupling

- High-performance gearbox

- Jbj-Techniques Limited spring brake

- Electric motor gearbox

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.