- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Automatic filler AsepTec®for jarsbottlebeverage

Add to favorites

Compare this product

Characteristics

- Operational mode

- automatic

- Container type

- for jars, bottle

- Product applications

- beverage, for milk, for low-viscosity liquids, for high-viscosity products, for dairy products

- Domain

- for the food industry

- Type

- aseptic

- Other characteristics

- aseptic

Description

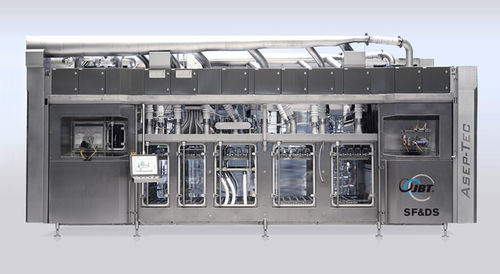

Our AsepTec® linear aseptic filler is unique, standing out by the range of products and bottles (HDPE, PP, PET) it can handle, its high speed, its reliability and its flexibility.

The AsepTec filler was designed, from the ground up, to provide carefully controlled and verifiable filling conditions and to meet the strict requirements of the validation-by-design concept. By identifying the factors which reduce the reliability and sterile conditions of conventional fillers, we avoided them in our new design–thus creating a new generation of aseptic filler.

Standard capacities are 12,000 BPH, 18,000 BPH, 24,000 BPH, and 30,000 BPH.

Features & Benefits

Efficient and reliable

Effective decontamination

Unique air management system

Precise filling

Low utility consumption

Sophisticated user interface and control system

Possibility to change between different container shapes, sizes, and product in less than 30 minutes without breaking sterility

Can fill particulates up to 9 mm x 9 mm x 9 mm (0.35″ x 0.35″ x 0.35″)

Can seal bottle with foil seal or aseptic screw cap

Details

AsepTec fillers can handle high and low viscosity products and even products containing solids, therefore, a single filler can handle your full product range.

VIDEO

Catalogs

Related Searches

- Automatic filler

- Liquid filler

- Automatic labelling machine

- Filler for the food industry

- Bottle filler

- Food product filling machine

- Volumetric filler

- Semi-automatic filler

- Multi-head filler

- Filler for the pharmaceutical industry

- Sealer

- Labeling machine for the food industry

- Case packer

- Container filler

- Automatic case packer

- Piston filler

- Bag filler

- Weight filler

- Compact filler

- Tray sealing machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.