- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

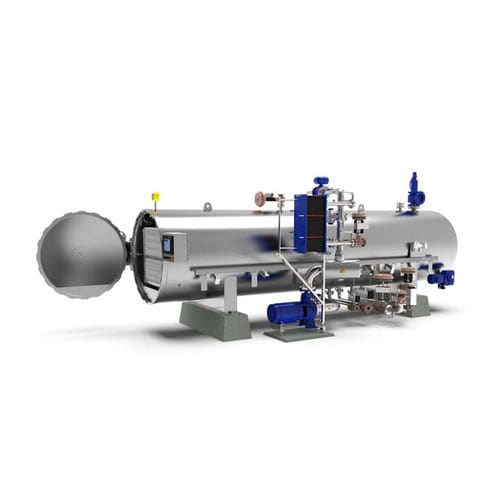

Process retort Steam Water Spray™ (SWS)for the food industrysterilization

Add to favorites

Compare this product

Characteristics

- Laboratory/process

- process

- Applications

- for the food industry, sterilization

- Effective capacity

Max.: 17,280 US fl oz

Min.: 960 US fl oz

Description

Steam is directly injected in the bottom of the retort for fast and uniform come-up. Water sprays running over the entire shell length intensely mix the steam and water and create a homogeneous temperature distribution that results in a uniform process throughout the retort. Indirect, sterile cooling via a plate heat exchanger saves water and eliminates the need for water treatment chemicals.

FEATURES & BENEFITS

Reduced process time

Efficient heat distribution

Absolute flow meter and level probe

High quality design and construction

Micro cooling

Precise temperature and pressure control

Precise, reproducible execution of pre-programmed recipes

Ultimate container flexibility: rigid containers (bottles, cans, etc.); semi-rigid (tubs, etc.) and flexible (pouches, etc.)

DETAILS

Retorts are at the heart of many shelf-stable food processing lines such as:

Ready-meals

Baby food, pet food, soups, sauces

Mushrooms, vegetables, beans, and more

Milk (plain, chocolate, milkshakes, cream, etc.)

Fruits juices, non-carbonated beverages, tea, coffee, etc.

Catalogs

SuperStatic Retort

4 Pages

Related Searches

- Drying system

- In-line dryer

- Air blast drying system

- Drying system for the food industry

- Batch dewatering system

- Retort

- Centrifugal dewatering system

- Heat sterilizer

- Drying system with belt conveyor

- Fluidized bed dryer

- Stainless steel drying system

- Process sterilizer

- Sterilization retort

- Process retort

- Automatic autoclave

- Sterilizer for the food industry

- Curing drying system

- Steam sterilizer

- Automatic sterilizer

- Coating dryer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.