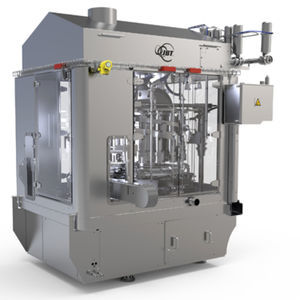

Glass bottle filler Preci fill™for plastic bottlescancup

Add to favorites

Compare this product

Characteristics

- Container type

- for glass bottles, for plastic bottles, can, cup

- Product applications

- fruit juice, sauce, for food, for viscous products

- Domain

- for the food industry

- Type

- rotary, weight

- Other characteristics

- compact, high weight precision

- Throughput

30,000 p/h

Description

Our rotary weight filler is an extremely accurate, non-contact weight filling system which minimizes product give-away. This filler handles plastic and glass bottles, plastic cups, glass jars and cans; it’s equipped with effective Clean-in-Place provisions and can be equipped with a conditioned filling space to meet hygienic filling requirements. The system can be combined with a bottle rinsing unit and a capper/sealer to form a mono-block machine, which leads to reduced footprint, faster format change-over and greater reliability. We offer these fillers in different dairy fill types in order to meet the customer’s needs in terms of shelf life (standard, high hygienic and ultraclean).

• Highly accurate filling, minimum give away

• Non-contact filling

• Compact filling space

• Up to 30,000 bottles/hour at full speed

• Covers a wide range of high and low viscosity products

• Reduced number of couplings to improve reliability and facilitate maintenance

• Internal CIP system included with possibility of external CIP (ultraclean dairy fill version)

• Increased airflow through the HEPA filters in order to prevent any ingress of ambient air

Catalogs

No catalogs are available for this product.

See all of JBT‘s catalogsRelated Searches

- Automatic filler

- Liquid filler

- Filler for the food industry

- Bottle filler

- Food product filling machine

- Volumetric filler

- Multi-head filler

- PLC-controlled filler

- Container filler

- Piston filler

- Bag filler

- Weight filler

- Compact filler

- High-speed filler

- Can filler

- Rotary filler

- Filler with conveyor

- PET bottle filling machine

- Sauce filler

- Filler with 1 head

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.