- Production Machines

- Other Manufacturing Equipment

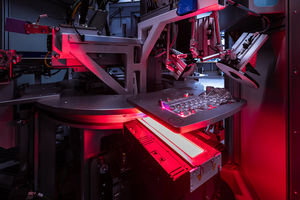

- Optical inspection machine

- JENOPTIK Industrial Metrology Germany GmbH

- Products

- Catalogs

- News & Trends

- Exhibitions

Optical inspection machine Visionline B seriessurfaceboreindustrial

Add to favorites

Compare this product

Characteristics

- Technology

- optical

- Applications

- surface, bore

- Sector

- industrial

- Other characteristics

- high-resolution

Description

Visionline B sensors are especially suitable for bore surfaces. They impress with their 360° all-round vision optics. In this automatic process, a CMOS sensor completely scans the inner surface of the bore and delivers high-resolution and high-contrast images. This allows for the detection of surface defects such as blowholes, porosity and scratches even during production. With Evovis Vision software, your employees evaluate the images easily and intuitively.

Innovative camera and illumination technology, adaptive dynamic masking, and high resolution enable automated 100 % inspection of bores within the required cycle time of the production process. The systems allow a fast inspection of the complete bore surfaces, as well as the classification of defect areas.

Sensors:

- Visionline B5 for bores from 5 mm

- Visionline B20 for bores from 14 mm

- Visionline B100 for bores from 68 mm

VIDEO

Catalogs

No catalogs are available for this product.

See all of JENOPTIK Industrial Metrology Germany GmbH‘s catalogsOther JENOPTIK Industrial Metrology Germany GmbH products

Optical Surface Inspection

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.