- Products

- Electro-pneumatic transducer

- JENOPTIK Industrial Metrology Germany GmbH

- Products

- Catalogs

- News & Trends

- Exhibitions

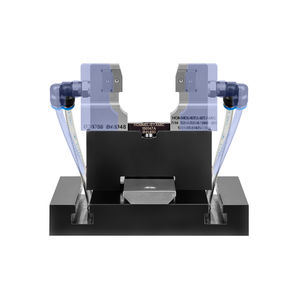

Electro-pneumatic transducer Gageline TPE200

Add to favorites

Compare this product

Description

The electro-pneumatic TPE200 transducer allows you to transfer pneumatic measuring signals in numeric format. This enables quick and reliable analysis and evaluation of the results.

The Hommel-Etamic TPE200 converts the results of your dynamic, pneumatic measurement into a digital CANopen signal. It serves as the link between the pneumatic gauging component and a measuring computer. The transducer ensures that you are able to display and analyze your measured values. It operates with great speed and reliability, while performance is equally impressive with measurement noise of less than 0.1 µm and a response time of just 15 ms.

All electro-pneumatic transducers strictly comply with the DIN 2271 standard for pneumatic metrology. Your measured results are therefore completely reliable and transparent.

The minimal noise levels of the TPE200 have virtually no impact on your measurements. All data is transferred with utmost reliability, thus allowing you to produce workpieces of consistently high quality. Thanks to its robust and compact design, you can mount the electro-pneumatic transducer directly on the gauging component or easily integrate it in various machines.

Benefits

• Fast: Rapidly converts your measuring signals.

• Minimal measurement noise: Flawless transfer of results.

• No interference: The transducer transmits data with utmost reliability.

• Versatile: Suitable for in-process, post-process and offline applications.

Applications

• Automotive industry: Integration in through-feed grinding or honing machines.

Catalogs

No catalogs are available for this product.

See all of JENOPTIK Industrial Metrology Germany GmbH‘s catalogsOther JENOPTIK Industrial Metrology Germany GmbH products

Dimensional Metrology

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.