FIB/SEM microscope CRYO-FIB-SEMindustrialfluorescence

Add to favorites

Compare this product

Characteristics

- Type

- FIB/SEM

- Technical applications

- industrial

- Observation technique

- fluorescence

Description

This CRYO-FIB-SEM system incorporates a liquid nitrogen cooling stage and a cryocooled specimen transfer mechanism for frozen specimens, making it possible to prepare TEM specimens such as biopolymers.

The specimen transfer mechanism has a built-in sputter coating function. Therefore, this CRYO-FIB-SEM system alone can perform a series of processes to create TEM specimens from frozen specimens including conductivity coating, protective film forming, and FIB processing.

In addition, by using JEOL's CRYO ARM™ cartridge, direct specimen transfer to the CRYO ARM™ after TEM specimen preparation becomes easier.

Features

• Cryo Specimen Transfer Using CRYO ARM™ Cartridge

After attaching a specimen mesh to the cartridge, it is no longer necessary to handle the specimen mesh using tweezers, so high-throughput specimen transfer can be performed.

• Highly Stable Cooling Stage

The thermal conductivity cooling stage reduces stage drift and vibration caused by the cooling process and realizes steady TEM specimen preparation.

• JEOL's Unique Anti-Contamination Device

With this newly developed anti-contamination device, ice contamination in the specimen chamber is reduced. Even during prolonged preparation of large specimen amounts, the device suppresses ice contamination to the fullest extent.

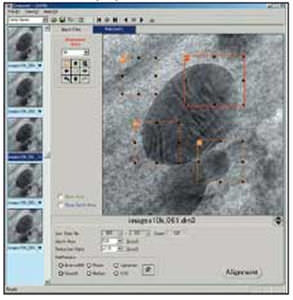

Cryo CLEM Workflow

A cryo-CLEM workflow using the CRYO ARM™ cartridge can be constructed using a cryostage manufactured by Linkam Scientific Instruments* and a fluorescence microscope manufactured by Nikon Solutions*. The stage coordinates of each instrument can be linked, so the orientation and position of the specimen can always be identified during specimen transfer between instruments.

Catalogs

No catalogs are available for this product.

See all of Jeol‘s catalogsRelated Searches

- Jeol microscope

- Jeol laboratory microscope

- Tabletop microscope

- Digital camera microscope

- Jeol analysis microscope

- Bright field microscope

- Jeol high-resolution microscope

- Industrial microscope

- Jeol automated microscope

- Compact microscope

- Fluorescence microscope

- Medical microscope

- Black field microscope

- Specimen maker

- 3D microscope

- Jeol electron microscope

- Automatic sample preparation system

- High-speed microscope

- Real-time microscope

- Multipurpose microscope

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.