- Industrial machines and equipment

- Welding and Assembly

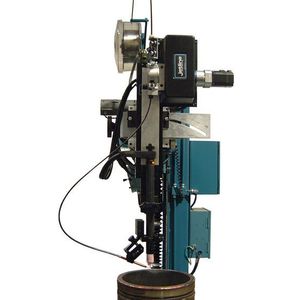

- Welding wire feeder

- Jet Line Engineering

Welding wire feeder CWF series

Add to favorites

Compare this product

Characteristics

- Wire type

- for welding

Description

Cold wire feeders are designed to supply filler metal into the weld puddle during GTAW or PAW. Cold wire feeders provide more accurate wire feed at lower speeds and are specially insulated for the GTAW or PAW environment.

9629 microprocessor control with user friendly software

Can increase weld travel speeds with certain materials

Some applications require wire to avoid cracking in sensitive materials

The addition of wire helps to chill the weld puddle

Adds reinforcement to a butt weld or adds wire to a prepared weld joint

Provides filler material for an overlay or cladding operation

Offers a four-roll feed head with precision motor and tach generator

Feeds wire diameters ranging from .020

to .093

(0.5 to 2.4 mm)

Closed loop speed control is standard

Models:Standard and precision models available

CWF-50 standard cold wire feeder; wire speed range of 4 to 200 IPM (100 to 5080 mm/min) at an accuracy of 1% of the maximum speed

CWF-20C precision cold wire feeder; wire speed range of 0.6 to 300 IPM (15 to 7600 mm/min) at an accuracy of 0.1% of the maximum speed

Catalogs

No catalogs are available for this product.

See all of Jet Line Engineering‘s catalogsRelated Searches

- Welding system

- Automatic welding system

- Metal welding system

- Precision welding system

- Arc welding system

- Manual welding system

- Resistance welding system

- Compact welding system

- CNC welding system

- Benchtop welding system

- Welding carriage

- TIG welding system

- Pipe welding system

- Seam welding system

- Copper welding system

- Longitudinal welding machine

- Welding rotator

- Welding wire feeder

- Motor-driven welding carriage

- Beam traveling welding carriage

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.