- Robotics - Automation - Industrial IT

- Industrial Software

- CAD/CAM software

- JETCAM International

Programming software JETCAM Expert CAD/CAMautomationCNC cutting machine

Add to favorites

Compare this product

Characteristics

- Function

- programming, CAD/CAM, automation

- Applications

- CNC cutting machine

Description

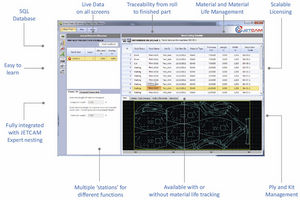

CADCAM and nesting for sheet metal and composite cutting

Whether you are a job shop producing small runs or a multi-national company looking for complete automation, JETCAM Expert CADCAM software delivers a comprehensive programming system for all CNC punching and profiling machines - including combination machines and machines with loading/unloading equipment and/or right angle shearing. Automation features such as Remote Control Processing (RCP) allow JETCAM Expert to be tightly integrated into existing data systems such as MRP, and provide feedback for Industry 4.0 (IoT) strategies.

CNC technologies supported

Punch -

Laser -

Combination

Waterjet -

Sonic Knife

Plasma/Oxyfuel

Routing

JET-Cut automatic fly cutting and JET-Optimizer

JET-Cut and JET-Optimizer are major steps forward in the automation of laser machines. JET-Cut allows 'fly cutting', also known as grid cutting, to be applied to arrays of holes. Unlike other systems this happens fully automatically. In tests, cut times for complex components are regularly reduced by 25-50%.

JET-Optimizer highly optimizes the sequence of cutting internal holes to minimize machine movements while avoiding travel over already cut holes.

Case Study: I-Cherng Refrigeration.

A user of JETCAM since 1995, I-Cherng were persuaded to take software supplied with their new Amada fiber laser. After a month of struggling they contacted JETCAM and purchased a postprocessor and an update to the latest version, which included JET-Cut fly cutting. As a result they saw an increase in throughput of 13.2%, reduced programming time by 80% and also saw material yields improve by 5-30%.

VIDEO

Catalogs

jetterm

2 Pages

Related Searches

- Automation software solution

- Computer-aided design software

- Control software solution

- Real-time software solution

- Interface software

- Programming software

- Network software solution

- Machine software

- Creation software

- Tracking software solution

- Editing software

- CAD/CAM software

- Android software solution

- Traceability software

- CAPM software

- Cutting machine software

- IOS software

- Nesting software

- Production management software solution

- Sheet metal software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.