- Machine-tools

- Machining Center

- CNC lathe

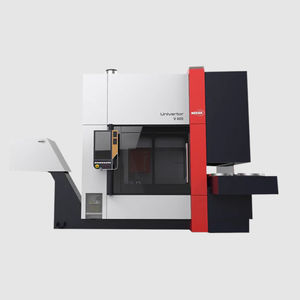

- J.G. WEISSER SÖHNE

CNC turning center UNIVERTOR AM2-axiscolumn type2-spindle

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Number of axes

- 2-axis

- Structure

- column type

- Number of spindles

- 2-spindle

- Number of tool stations

- 12 tools, 8 tools

- Performance

- high-productivity, powerful, precision

- Other characteristics

- compact

- Associated function

- milling, grinding, drilling

- Diameter

360 mm, 450 mm

(14.17 in, 17.72 in)- Spindle speed

3,500 rpm

(21,991.149 rad.min-1)- Bar capacity

120 mm

(5 in)- Axe X

1,400 mm

(55 in)- Axe Z

350 mm, 440 mm

(14 in, 17 in)- Rapids on X

60 m/min

- Rapids on Z

30 m/min

- Nominal power

35 kW, 35.1 kW, 40 kW

(47.6 hp, 47.7 hp, 54.4 hp)- Maximum torque

430 Nm, 610 Nm

(317 ft.lb, 450 ft.lb)

Description

Highly ribbed monobloc machine base

Long travels despite compact external machine dimensions

Precision linear guide ways in horizontal and vertical direction

The modularly designed vertical precision turning machines of the UNIVERTOR AM are highly flexible and predestined for the complete machining of different batch sizes at lowest costs per piece. Technology integrations of rotation turning, hard turning, grinding, drilling, milling in one workspace enable high workpiece quality, contour accuracy and surface finish. In addition, setup, programming and idle times are significantly reduced. Highly productive simultaneous machining in one machine with up to two powerful disc turrets realize intelligent technology processes.

In the working area of the UNIVERTOR AM-T with vertical spindle-slide arrangement and multifunction slide, the workpieces are cycled through the machine according to the transfer principle. The transfer takes place directly from the hanging pick-up spindle into the standing vertical spindle. The additional turrets, drilling heads or multifunctional slides mounted on the special column module enable a wide range of machining options. In this way, subsequent operations can be carried out in one work area with significantly reduced non-productive times and with maximum transfer precision between the clamping units. This guarantees highly accurate form and position tolerances on the workpieces.

Two-spindle design with pick-up spindle and vertically positioned counter spindle

Workpiece passage from left to right or vice versa possible

Machine column with very good stiffness behavior and optimized damping properties due to remaining sand in the model

VIDEO

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.