- Machine-tools

- Machining Center

- CNC lathe

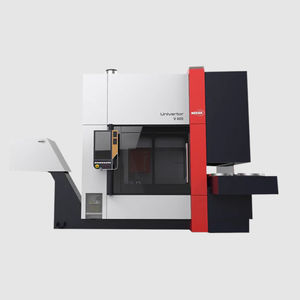

- J.G. WEISSER SÖHNE

CNC turning center VERTOR C/M2-axiscolumn type12 tools

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Number of axes

- 2-axis

- Structure

- column type

- Number of tool stations

- 12 tools

- Applications

- for large workpieces

- Performance

- high-precision, high-rigidity

- Other characteristics

- compact

- Diameter

450 mm

(17.72 in)- Spindle speed

1,100 rpm, 1,500 rpm, 3,500 rpm, 6,000 rpm

(6,911.504 rad.min-1, 9,424.778 rad.min-1, 21,991.149 rad.min-1, 37,699.112 rad.min-1)- Axe X

230 mm, 280 mm

(9 in, 11 in)- Axe Z

280 mm, 400 mm

(11 in, 16 in)- Rapids on X

30 m/min

- Rapids on Z

30 m/min

- Nominal power

18 kW, 23 kW, 52 kW, 67 kW

(24.5 hp, 31.3 hp, 70.7 hp, 91.1 hp)- Maximum torque

115 Nm, 146 Nm, 450 Nm, 580 Nm

(85 ft.lb, 108 ft.lb, 332 ft.lb, 428 ft.lb)

Description

Heavily ribbed monobloc machine base

Extremely high stiffness and thermal stability

Large working volumes with compact external dimensions of the machine

The machines of the Vertor C and M series are ideally suited for wet and dry machining of all common rotation-symmetrical workpieces with the highest precision, availability and continuous accuracy. The machines have very good accessibility with minimum space requirements and also offer the option for two or four axes. Technology integration of innovative processes such as out-of-round turning, hard turning, grinding, drilling or milling result in a significant reduction of in-house logistics processes and create high-precision machining results. The multifunctional vertical turning machines are among the world’s best machine tools in their class in terms of operating speed, availability, stability and reliability.

Direct drives

Slide design for high accuracies and dynamics

Linear path measuring systems in horizontal and vertical direction

Maintenance-free three-phase servo drives

Machining of chuck turned parts or shafts with tailstock and steady rest support

4-axis design for reduced Machining times

Driven tools

Optimized for manual loading

VIDEO

Catalogs

VERTOR C VERTOR M

11 Pages

Related Searches

- Turning center

- CNC turning center

- 2-axis turning center

- High-precision turning center

- 12 tools turning center

- High-performance turning center

- High-rigidity turning center

- Vertical turning center

- High-productivity turning center

- Turning-milling machine

- CNC turning-milling center

- Powerful turning center

- Milling turning center

- Compact turning center

- Precision turning center

- Horizontal turning-milling center

- Spindle turning-milling center

- Multi-spindle turning machine

- Drilling turning center

- Large part turning center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.