- Machine-tools

- Machining Center

- CNC lathe

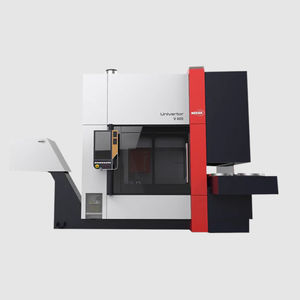

- J.G. WEISSER SÖHNE

CNC turning center UNIVERTOR AC series 2-axis12 toolshigh-precision

Add to favorites

Compare this product

Characteristics

- Control type

- CNC

- Number of axes

- 2-axis

- Number of tool stations

- 12 tools

- Performance

- high-precision, high-productivity, powerful

- Associated function

- grinding

- Diameter

150 mm

(5.91 in)- Spindle speed

1,600 rpm

(10,053.096 rad.min-1)- Bar capacity

90 mm

(4 in)- Axe X

830 mm

(33 in)- Axe Z

180 mm

(7 in)- Rapids on X

60 m/min

- Rapids on Z

30 m/min

- Nominal power

16.8 kW, 20.9 kW, 21.5 kW, 26.8 kW

(22.8 hp, 28.4 hp, 29.2 hp, 36.4 hp)- Maximum torque

100 Nm, 128 Nm, 200 Nm, 255 Nm

(74 ft.lb, 94 ft.lb, 148 ft.lb, 188 ft.lb)

Description

Left and right machine variants available

Linear guides designed with high accuracy and preload classes in all machine axes

Direct path measuring systems in all machining axes (glass scales)

The machines of the AC-1 series are highly flexible and predestined for the complete machining of different batch sizes, with very high quality requirements. The design as a right-hand or left-hand machine concept realizes the ideal adaptation to the production sequence. Highly productive simultaneous machining in one machine with up to two powerful disk turrets (4 axes) or several grinding spindles enables intelligent technology processes with high savings potentials and creates high-precision machining results.

Left and right machine variants available

Machine columns with very good stiffness behavior and optimized damping properties due to remaining sand in the model

Linear guides designed in high accuracy and preload classes in all machine axes

All linear guides and feed drives arranged outside the working area for protection against chips

Direct path measuring systems in all machining axes (glass scales))

High dynamics of all machine axes

Optimal chip fall downwards

Self-built turning spindles with very good concentricity and axial run-out accuracy values

Easy installation and removal of the turning spindle in the event of repairs

Compact footprint due to integrated handling unit (2-axis version with swivel unit)

Main spindle A6 according to DIN 55026

Interface in tool turret VDI or Capto possible

Integrated measuring probe possible

Driven tools possible (for drilling operations)

4-axis machining possible (by additional turret on cross slide unit)

VIDEO

Catalogs

No catalogs are available for this product.

See all of J.G. WEISSER SÖHNE‘s catalogsRelated Searches

- Turning center

- CNC turning center

- 2-axis turning center

- High-precision turning center

- 12 tools turning center

- High-performance turning center

- High-rigidity turning center

- Vertical turning center

- High-productivity turning center

- Turning-milling machine

- CNC turning-milling center

- Powerful turning center

- Milling turning center

- Compact turning center

- Precision turning center

- Horizontal turning-milling center

- Spindle turning-milling center

- Multi-spindle turning machine

- Drilling turning center

- Large part turning center

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.