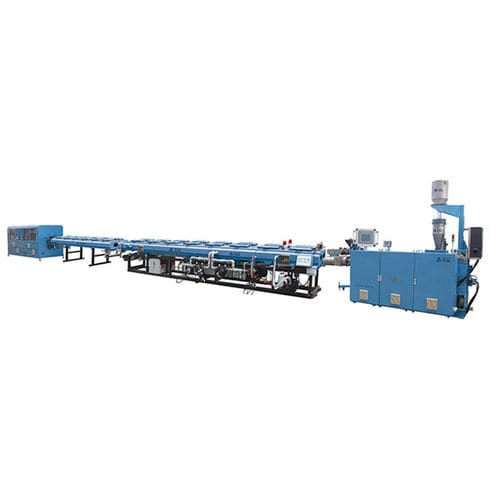

High efficiency PP-R PE-RT PB pipes are widely used in the uptown apartment and village cables protection hot water supplying house heating. This production line adopts high efficiency single screw extruder equipped with the Siemens PLC controlling system. It can ensure the whole line automatic controlling of high capacity stable extruding with the suitable changing of different units could realize the production job of PP-R PE-RT PB pipe.

The advantages are as following:

a. It’s for high speed extruding PE PPH PPR PPB PERT and PB etc line speed is up to 25m/min.

b. L/D=38 double mixer and barrier screw which can ensure 100% plasticization before going into die with spiral groove on feeding part it increases 30% of productivity.

c. Die with spiral mandrel it ensures no delay in the flow channel which can improve pipe quality.

d. Particular disc design on calibration sleeves which ensures high speed extrusion.

e. Double-strand vacuum tank is controlled individually which makes convenient operation as single one.

f. Double haul-off is also controlled individually which makes convenient operation as single strand additionally with the upper caterpillar belt stop device to ensure roundness of pipe.

g. With individual designed of chipless cutter. Driven by motor and synchronous belts which ensures normal cutting during high speed running.

Such production line has being working perfect at the moment in Russia Poland New Zealand Australia Philippines Malaysia and many other countries.