- Production Machines

- Plastics Processing

- Co-rotating twin-screw extruder

- Jiangsu Xinda Tech Limited

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

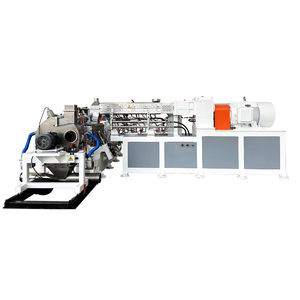

Co-rotating twin-screw extruder PSHJ-65clamshell barrel

Add to favorites

Compare this product

Characteristics

- Number of screws

- co-rotating twin-screw

- Other characteristics

- clamshell barrel

- Output

400 kg/h

(881.849 lb/h)Max.: 800 kg/h

(1,763.6981 lb/h)Min.: 300 kg/h

(661.3868 lb/h)- Screw diameter

75 mm

(3 in)Max.: 132 mm

(5.2 in)Min.: 20 mm

(0.8 in)- Screw length

2,000 mm

(79 in)Max.: 3,000 mm

(118 in)Min.: 840 mm

(33 in)- Maximum speed

600 rpm

(3,770 rad.min-1)Max.: 800 rpm

(5,027 rad.min-1)Min.: 100 rpm

(628 rad.min-1)- Torque

10 Nm

(7 ft.lb)Max.: 12 Nm

(9 ft.lb)Min.: 8 Nm

(6 ft.lb)- Temperature

200 °C

(392 °F)Max.: 400 °C

(752 °F)Min.: 1 °C

(34 °F)- Maximum pressure

12 bar

(174 psi)Max.: 15 bar

(217.6 psi)Min.: 5 bar

(72.5 psi)- Overall length

3,000 mm

(118 in)Max.: 5,540 mm

(218 in)Min.: 840 mm

(33 in)- Overall width

1,000 mm

(39 in)Max.: 1,500 mm

(59 in)Min.: 800 mm

(31 in)- Total height

2,000 mm

(79 in)Max.: 2,500 mm

(98 in)Min.: 1,000 mm

(39 in)- Weight

3,000 kg

(6,614 lb)Max.: 6,000 kg

(13,228 lb)Min.: 1,000 kg

(2,205 lb)- Power

160 kW

(217.54 hp)Max.: 480 kW

(652.62 hp)Min.: 5 kW

(6.8 hp)

Description

Clam shell Barrel

--The barrel can be opened in minutes. This makes

product changeover, maintenance and research fast

and easy.

Visible for inspection

--The barrel could be easily opened to check the

internal mixing situation inside the extruder. Thus

the researchers could make the adjustment based

on the dispersiveness and the distributiveness of

the compounds.

Modular construction

--The XINDA PSHJ twin screw series are built on a

modular system. The major advantage of this modular

design is the versatile configurations.

Processing tasks can be optimally accomplished with

only a few barrel and screw variations.

XINDA lab scale extruder has fewer number of liners,

which is easy for changeover.

Barrel Section- Separately controlled

--The modular principle of the barrel permits precise

sequencing for each application. Each barrel section"s

temperature can be set separately.

Electrical heater shells provide for heating, cooling is

obtained with water. Barrels, as well as screw and

kneading elements are made out of nitride steel in the

standard version;

The wear resistant version is made of suitable

materials, corresponding to the respective

requirements.

Reliable Electrical System

--Siemens PLC controlling system with

user-friendly touch screen

SIEMENS inverters

Omron temperature sensor

Siemens electrical parts

Italian electric-magnetic Valve

Catalogs

XINDA Twin Screw Extruder

4 Pages

Other Jiangsu Xinda Tech Limited products

Twin Screw Extruder

Related Searches

- Pelletizer

- Screw extruder

- Twin-screw screw extruder

- Plastic pelletizer

- Single-screw screw extruder

- Compounding screw extruder

- PP screw extruder

- PE screw extruder

- ABS screw extruder

- PVC screw extruder

- Compact screw extruder

- Pelletizer for the plastics industry

- Laboratory screw extruder

- PS screw extruder

- PET screw extruder

- Masterbatch screw extruder

- Pelletizing screw extruder

- PC extruder

- Co-rotating twin-screw screw extruder

- Underwater pelletizer

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.