- Production Machines

- Cutting Machine

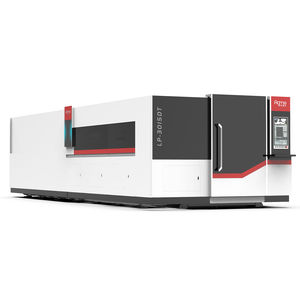

- Laser cutting machine

- Jinan Acme CNC Equipment Co., Ltd.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Laser cutting machine LT-8012EAfor metaltubeCNC

Add to favorites

Compare this product

Characteristics

- Technology

- laser

- Material

- for metal

- Product handled

- tube

- Control type

- CNC

- Associated function

- drilling

- Applications

- for metal fabrication, for aeronautical applications, for the electronics industry, for medical applications, for the food industry, for processing industry, for the toy industry

- Workpiece loading

- with automated loading

- Phase

- three-phase

- Other characteristics

- high-precision, automatic, high-speed, precision, high-performance, CE, heavy-duty, high-efficiency, with water cooling, modular, with servo-motor, high-power, for steel construction, economical, programmable

- X travel

8,500 mm

(334.65 in)- Y travel

500 mm

(19.69 in)- Z travel

300 mm

(12 in)- Cutting speed

15,000 mm/min

(9.843 in/s)

Description

LT-8012EA Advantages of Fiber Tube Laser Cutting Machine

1. High precision: suitable for precision parts cutting and cutting of various process words.

2. Welded aluminum collet board, formed through high precision process. Good weight and good dynamic performance.

3. Small heat affected zone, not easy to deform, smooth and beautiful cutting seam, without follow-up treatment.

4. High cost performance, low use cost and low follow-up maintenance costs.

5. Stable sex, maintain continuous production.

6. Good rigidity, high precision, no deformation during the life cycle;

Core Components: Fiber Laser

Mode of Operation: continuous wave

Configuration: 4-axis

Products handled: Sheet Metal

Feature: Servo motor

Product name: laser plate cutting machine

Laser Source: Max/Raycus/Ipg

Laser head: Raytools/Precitec

Control system: Fscut Tube Pro 3000s

Servo Motor: YASKAWA/Panasonic

Reducer: Shimpo

Guiding Rail: HIWIN, Taiwan

Rack: YYC, Taiwan

Electrical parts: Schneider

Applicable Industry:

Automobile manufacturing, machinery and equipment, electrical equipment, hotel kitchen equipment, elevator equipment, advertising logo,car decoration, sheet metal production, lighting hardware, display equipment, precision parts, hardware products, subway accessories, decoration, textile machinery, food machinery , Construction machinery, ships, tooling, metallurgical equipment, aviation, aerospace and other manufacturing and processing industries.

Applicable Materials:

Laser Cutting machine is suitable for variety of metal plates, stainless steel, carbon steel, galvanized sheet, pickling plate, brass plate, aluminum plate, manganese steel, all kinds of alloy plates, rare metals etc.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Jinan Acme CNC Equipment Co., Ltd.‘s catalogsOther Jinan Acme CNC Equipment Co., Ltd. products

Others Products

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.