- Production Machines

- Cutting Machine

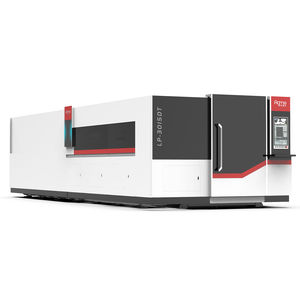

- Fiber laser cutting machine

- Jinan Acme CNC Equipment Co., Ltd.

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Fiber laser cutting machine LT-6025ESfor metalfor metal pipesCNC

Add to favorites

Compare this product

Characteristics

- Technology

- fiber laser

- Material

- for metal

- Product handled

- for metal pipes

- Control type

- CNC

- Applications

- for industrial applications, for the automotive industry, for the electronics industry, for processing industry

- Workpiece loading

- automated loading/unloading

- Configuration

- 5-axis

- Other characteristics

- completely automated, high-precision, high-speed, high-efficiency, high-power, heavy-duty

- Tube diameter

Max.: 240 mm

(9 in)Min.: 16 mm

(1 in)- Cutting speed

Max.: 92,000 mm/min

(60.367 in/s)Min.: 500 mm/min

(0.328 in/s)- Laser power

Max.: 12,000 W

Min.: 1,000 W

Description

Highlights of High Efficiency Laser Tube Cutting Machine LT-6025ES:

√Applicable to 250mm chuck with the highest utilization rate and cost saving.

√ Unique automatic loading and unloading, compared with general automatic feeders, the feeding speed is faster and more stable.

√ Automatic sorting and clearing.

● Perfectly solve the processing of pipes below 250mm in diameter

● Original automatic feeding and distribution system

● Speed - always one step faster

● Accuracy - consistently better than other laser tube cutters

High-efficiency laser pipe cutting machine application:

● Especially suitable for fitness equipment manufacturing, metal furniture industry, metal trolleys, stainless steel products manufacturing and other industries.

● Various types of pipes such as round, square, rectangular, oval and H-shaped.

● Stainless steel, carbon steel, aluminum, copper, brass, iron, etc.

Main parameters of high-efficiency laser pipe cutting machine:

● Pipe diameter range: round φ13mm-φ240mm; square 13mm-240mm

;Rectangular tube: 13mm-240mm; I-beam: 13mm-240mm; Angle steel; 13-240mm; Channel steel: 13mm-240mm

● Maximum positioning speed: X-axis 150m/min, Y-axis 120m/min

● Maximum speed: 200r/min

● Positioning accuracy: 0.03m

● Acceleration: 1.5g

VIDEO

Catalogs

Other Jinan Acme CNC Equipment Co., Ltd. products

Others Products

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.