- Production Machines

- Cutting Machine

- Fabric cutting table

- Jinan AOL CNC Equipment Co., Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

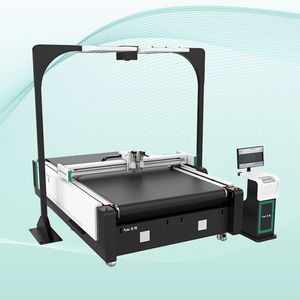

Fabric cutting table AOL-2125DPSfor plasticswith end cutting systemrotary-knife

Add to favorites

Compare this product

Characteristics

- Materials

- for fabric, for plastics

- Other characteristics

- with end cutting system, rotary-knife, for fabric padding

- Width

Max.: 2,100 mm

(83 in)2,020 mm

(80 in)Min.: 1,800 mm

(71 in)- Length

Max.: 2,500 mm

(98 in)2,320 mm

(91 in)Min.: 2,200 mm

(87 in)

Description

Why do most manufacturers choose graphite composite gasket cutting machines now?

Graphite composite gasket, also known as flexible graphite metal reinforced composite gasket, is a kind of sealing gasket which is composed of punched metal tooth plate or punched metal core plate and flexible graphite particles. It is usually composed of flexible graphite composite gasket. Reinforced panel cut.

There are a lot of pores in the graphite structure, so it is relatively loose and has a low density. Graphite has good lubricity and wear resistance, low flexural strength and compressive strength, high hardness and high brittleness. If you don't pay attention to the processing, the corners will crack and the edges will fall off. It is a relatively difficult material to process.

In response to this phenomenon, our company has developed a special cutting equipment for cutting gaskets—graphite composite gasket cutting machine. The cutting edge of this equipment is smooth and flat during the cutting process, and the cutting accuracy reaches ±0.1mm, which is 2-3 times higher than that of manual labor. Efficient, can be profiled cutting, and no need to make molds.

Graphite composite gaskets have good corrosion resistance, high/low temperature resistance, radiation resistance, good compression resilience and high strength, and are mainly used in various pipelines, valves, pumps, pressure vessels, heat exchangers, condensers , Generators, air compressors, exhaust pipes, refrigerators and other flange connections can replace asbestos rubber gaskets and iron-clad gaskets.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Jinan AOL CNC Equipment Co., Ltd‘s catalogsOther Jinan AOL CNC Equipment Co., Ltd products

Digital Gasket Cutting Machine

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Cutting machine for industrial applications

- Automatic cutting system

- Knife cutting system

- High-precision cutting system

- Sheet metal cutting system

- High-speed cutting system

- Tube cut-off machine

- Plastic cutting system

- Precision cutting system

- Fabric cutting system

- Sheet cutting system

- Cutting machine for the automotive industry

- CE cutting system

- High-performance cutting system

- Three-phase cutting system

- High-efficiency cutting system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.