- Production Machines

- Cutting Machine

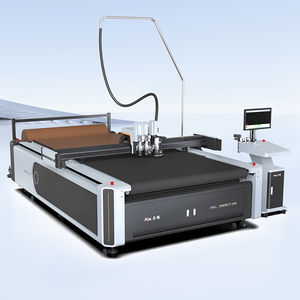

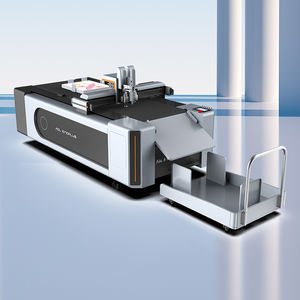

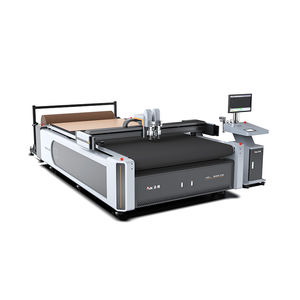

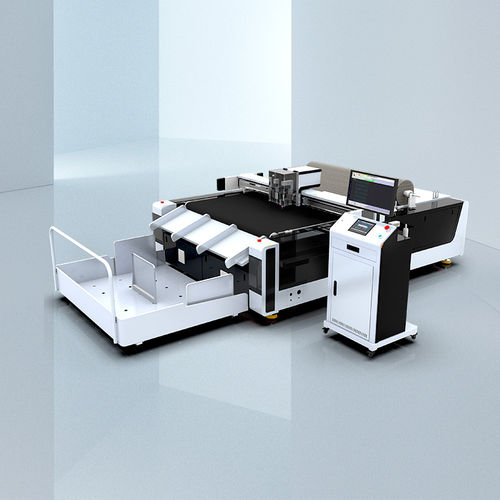

- Fabric cutting plotter

- Jinan AOL CNC Equipment Co., Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Fabric cutting plotter AOL-1612PLUSfor plasticsfor composite materialsfor paper and cardboard

Add to favorites

Compare this product

Characteristics

- Material

- for paper and cardboard, for fabrics, for composite materials, for plastics

- Other characteristics

- CNC, automatic, digital

Description

How does a vinyl cutter work?

Read our great article on how a vinyl cutter works and enter the fascinating world of precision and creativity. Uncover the magic behind these stylish machines that easily transform digital designs into intricate masterpieces. Get ready to explore the fusion of art and technology that makes vinyl cutting a truly fascinating endeavor. Don't miss out - click now to delve into a world of precision craftsmanship and artistic ingenuity!

It doesn't matter whether you're printing stickers, vinyl window screens or a full car wrap - a key piece of equipment in your print shop's arsenal is a vinyl cutter.

Whether you use an AOL vinyl cutter or another brand cutter, the results are usually the same. Some brands may offer features that others don't, but in the end, it comes down to your individual needs. So, how does a vinyl cutter work?

Blades and Lasers:

Both blade and laser vinyl cutters have their pros and cons; both options generally work the same way—the cutter feeds the vinyl in and cuts it as needed. The vinyl is then reversed through the machine to make a cut in another area or to change the shape of a cut currently in progress.

Instead of an in-feed system, some laser cutters place the vinyl on a table and the laser moves over the area to be cut. These are usually the fastest cutters on the market.

Vinyl cutters with blades are able to handle thicker, more durable materials that laser cutters cannot cut without burning the edges. For the thickest materials, a blade vinyl cutter is the best choice. For thinner materials, lasers offer unrivaled speed.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Jinan AOL CNC Equipment Co., Ltd‘s catalogsOther Jinan AOL CNC Equipment Co., Ltd products

Digital Advertising Printing Cutter

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Cutting machine for industrial applications

- Automatic cutting system

- Knife cutting system

- High-precision cutting system

- Sheet metal cutting system

- High-speed cutting system

- Tube cut-off machine

- Plastic cutting system

- Precision cutting system

- Fabric cutting system

- Sheet cutting system

- Cutting machine for the automotive industry

- CE cutting system

- High-performance cutting system

- High-efficiency cutting system

- Three-phase cutting system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.