- Production Machines

- Cutting Machine

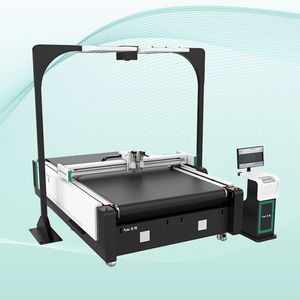

- Knife cutting machine

- Jinan AOL CNC Equipment Co., Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Knife cutting machine AOL-1625DCfor plasticsfor fabricsfor composite materials

Add to favorites

Compare this product

Characteristics

- Technology

- knife

- Material

- for plastics, for fabrics, for composite materials

- Product handled

- for foam panels, for sound-absorbing panels, for insulation panel, for honeycomb panels, for packaging, carpet, single-ply fabric, multi-ply fabric, cardboard box seal

- Control type

- CNC

- Associated function

- multi-function, milling

- Applications

- for industrial applications, for the automotive industry, for processing industry, for the toy industry, for the plastics industry, shoe industry

- Workpiece loading

- with automated loading

- Phase

- three-phase

- Configuration

- double-head

- Other characteristics

- completely automated, high-precision, high-speed, precision, high-performance, high-efficiency, ISO, electric, with automatic feeder, FDA

- X travel

Max.: 1,800 mm

(70.87 in)1,600 mm

(62.99 in)Min.: 1,400 mm

(55.12 in)- Y travel

Max.: 2,800 mm

(110.24 in)2,500 mm

(98.43 in)Min.: 2,200 mm

(86.61 in)- Z travel

Max.: 70 mm

(3 in)20 mm

(1 in)Min.: 0 mm

(0 in)- Maximum cutting height

Max.: 20 mm

(0.8 in)8 mm

(0.3 in)Min.: 10 mm

(0.4 in)- Tube diameter

Max.: 30 mm

(1 in)15 mm

(1 in)Min.: 1 mm

(0 in)- Cutting speed

Max.: 3 m/s

(9.843 ft/s)1 m/s

(3.281 ft/s)Min.: 0.1 m/s

(0.328 ft/s)- Laser power

Max.: 5,500 W

2,000 W

Min.: 500 W

- Repeatability

1 mm

(0.0394 in)- Resolution

Max.: 300 dpi

150 dpi

Min.: 72 dpi

- Acceleration

Max.: 10 m/s²

(33 ft/s²)5 m/s²

(16 ft/s²)Min.: 1 m/s²

(3 ft/s²)- Operating pressure

Max.: 1,100 bar

(15,954.15 psi)500 bar

(7,251.89 psi)Min.: 200 bar

(2,900.75 psi)- Overall length

3,000 mm

(118 in)- Overall width

2,000 mm

(79 in)- Height

1,300 mm

(51 in)- Weight

Max.: 2,400 kg

(5,291.09 lb)1,500 kg

(3,306.93 lb)Min.: 1,200 kg

(2,645.55 lb)

Description

Below are the materials that can be cut with our automatic gasket cutters:

Compressed Fibers – Compressed fibers can be cut using our CNC gasket cutters.

A variety of materials, including asbestos-free, PTFE-filled, fiberglass and Kevlar/Nitrile materials in sheet and roll form, can be placed on the bed table for cutting.

Rubber – Our automatic gasket cutters can cut rubber up to 1 inch (25 mm) thick.

Examples of soft rubber and semi-ridged rubber materials are neoprene, silicone rubber, rubber, butyl rubber, nitrile rubber, polyurethane, and diaphragm.

The machine can cut precise gaskets from these materials.

Foam and Sponge – Our CNC gasket cutters can cut foam or sponge up to 50mm thick and are best suited for flexible cutting. Semi-rigid foam or sponge.

Examples of closed cell sponge materials include neoprene, EPDM, PVC, polyester polyurethane, vinyl nitrile, nitrile rubber, silicone, epichlorohydrin, polyurethane, ethylene vinyl acetate (EVA), and natural open cell sponges.

Foam materials include crushed cell foam, cross-linked polyethylene foam, open cell polyurethane foam, and open cell polyurethane foam.

Plastic - Our gasket making machines can cut molded material or plastic material. The hardness and thickness of the plastic will affect the depth of the cut.

Cuts materials such as nylon, acetal, carbon fiber, polycarbonate, PTFE, acrylic, vinyl, and plastic laminates.

Cutting Felt and Fibers – Yes, felt and other fibrous materials can be cut with our gasket production machines.

Fibrous materials include high temperature ceramic fiber mats, ceramic papers, vegetable fibers and NBR carbon fiber sheets, which can be cut using a CNC operated shim cutter.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Jinan AOL CNC Equipment Co., Ltd‘s catalogsOther Jinan AOL CNC Equipment Co., Ltd products

Digital Gasket Cutting Machine

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Cutting machine for industrial applications

- Automatic cutting system

- Knife cutting system

- High-precision cutting system

- Sheet metal cutting system

- High-speed cutting system

- Tube cut-off machine

- Plastic cutting system

- Precision cutting system

- Fabric cutting system

- Sheet cutting system

- Cutting machine for the automotive industry

- CE cutting system

- High-performance cutting system

- Three-phase cutting system

- High-efficiency cutting system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.